摘要

木质素是自然界中天然储量仅次于纤维素的可再生高分子化合物,是制浆造纸产业的主要副产物之一,具有价格低、生产量大、易于降解的优点,其结构单元的化学结构与苯酚相似,因此可作为酚醛树脂的原料。木质素基酚醛树脂的制备与应用可以使大量生物质资源得到高价值利用,还能有效地缓解环境污染、石油资源短缺等问题,符合当今世界可持续发展的要求。本文综述了木质素基酚醛树脂的研究进展,分别介绍了含硫木质素基酚醛树脂与无硫木质素基酚醛树脂的制备工艺与应用现状,并总结了木质素基酚醛树脂发展存在的问题。

酚醛树脂是最早合成并实现工业化生产的合成树脂,是一类由酚类化合物和其他醛类化合物通过酚醛缩聚反应而成的高分子化合

木质素作为制浆过程的主要副产物,具有价格低、生产量大、易于降解的优点,并且具有独特的分子结构,富含多种功能基团,有良好的高值化利用前景。目前,木质素已应用于多孔炭材料、吸附材料、电容器电极材料、石墨烯材料、表面活性剂、水凝胶等高值化材料的制备,在能源、医疗、建筑、农业等领域都有着广阔的应用前

木质素的结构单元与苯酚化学结构相近,基于相似的化学结构,利用木质素部分替代苯酚制备木质素基酚醛树脂最具可行性。木质素及其衍生物可用于合成酚醛树脂燃料电池用双极板材

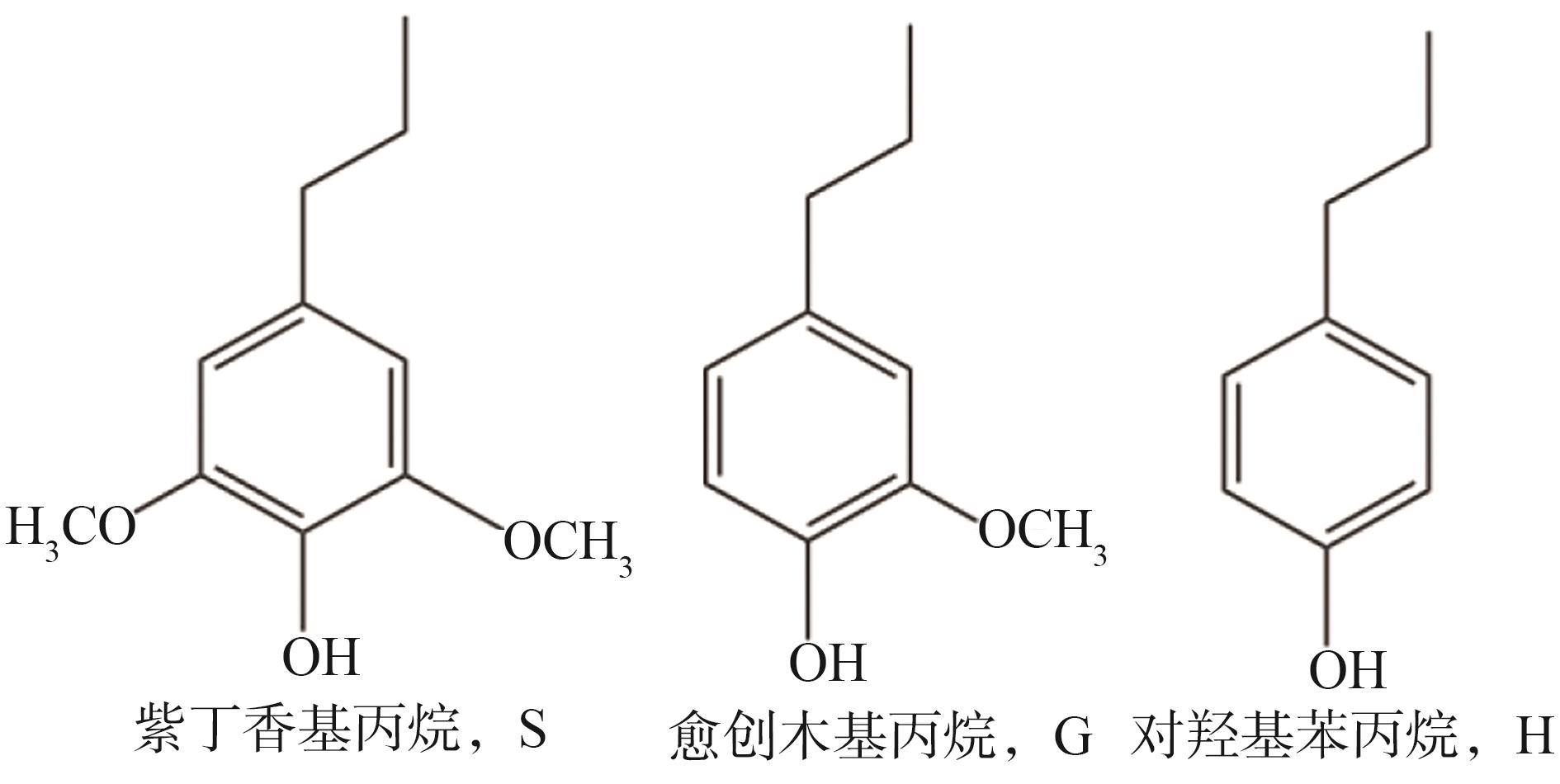

木质素是一种具有复杂结构的天然芳香族类高分子聚合物,其3种结构单元分别为紫丁香基丙烷(syringyl propane,S)、愈创木基丙烷(guaiacyl propane,G)、对羟苯基丙烷(p-hydroxyphenyl propane,H),如

图1 木质素的3种结构单元

Fig. 1 Three structural units of lignin

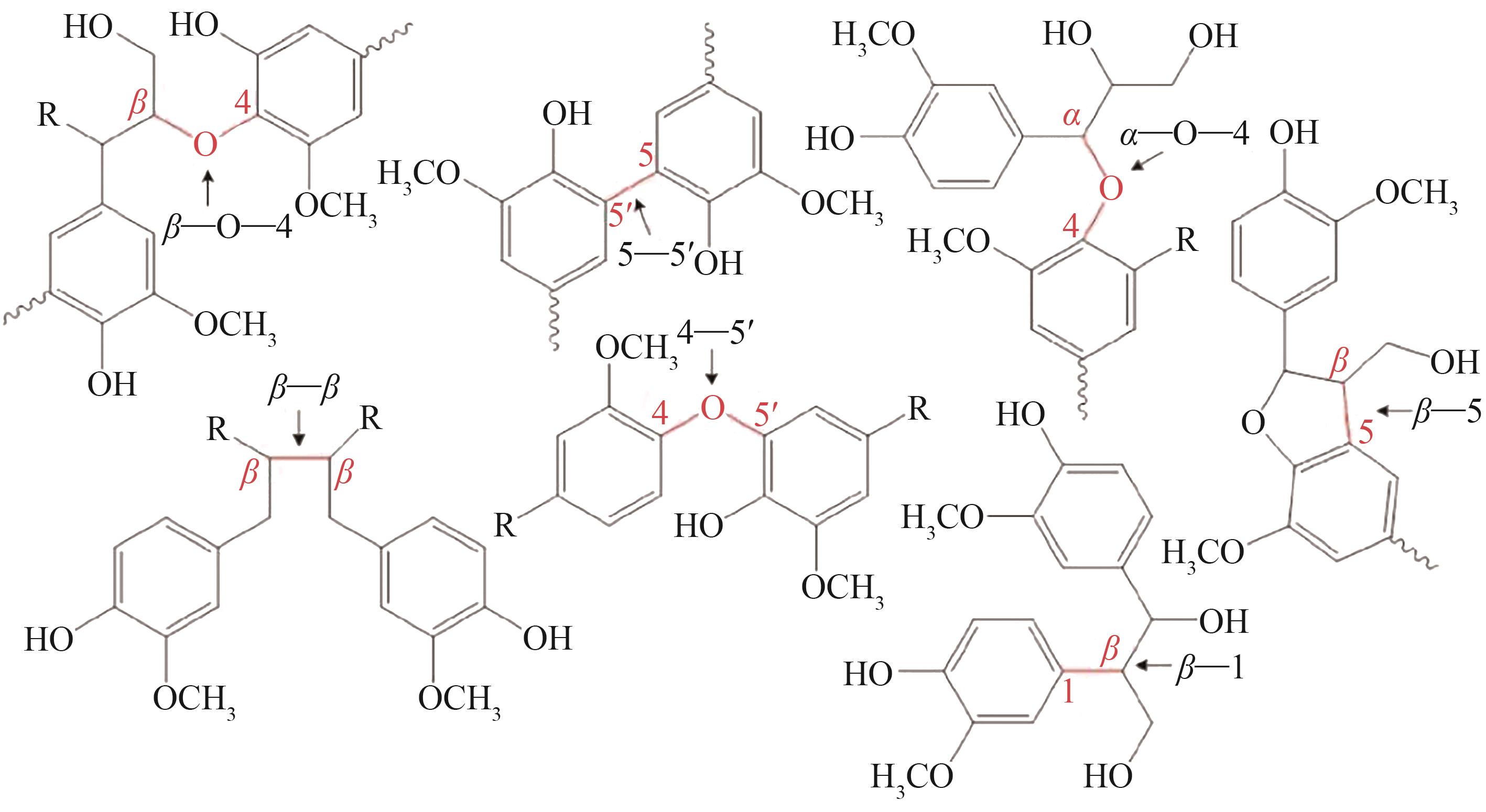

图2 木质素结构单元上的主要键接方

Fig. 2 Primany bond connections on lignin structural unit

在木质素的分子结构中有多种活性官能团,如芳香基、羟基、甲氧基、羰基、醛基,其中醛基和羟基含量较高,羟基存在形式为酚羟基和醇羟基。因此,木质素既能够提供羟基,又能够提供醛基,已被确定为石油衍生品(苯酚)的潜在替代品,用于制造酚醛树脂和聚氨酯树

目前市场上常见木质素大多都可根据硫的含量进行分类,分为含硫木质素和无硫木质素。

含硫木质素经萃取后含有无机复合硫,主要来源于造纸工业,最常见的类型是木质素磺酸盐和碱木质素。

木质素磺酸盐(lignosulfonate,LS)又称磺化木质素,主要从造纸工业的制浆废液中获取。由于在制浆废液中亚硫酸盐和木质素发生了磺化反应,生成木质素磺酸盐,所以其具有优良的水溶

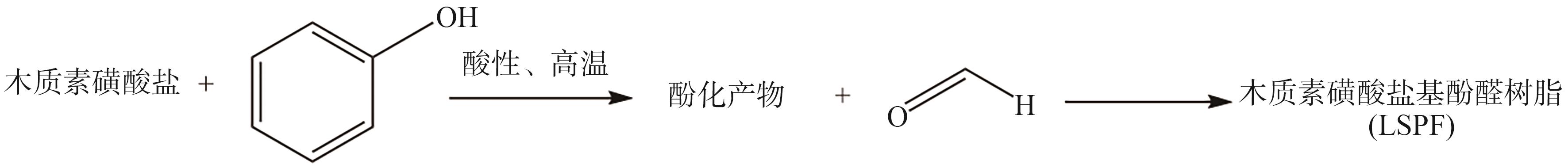

LS结构中的活性基团羟基可被利用于制备木质素磺酸盐酚醛树脂(lignosulfonate phenol-formaldehyde resin,LSPF

图 3 LSPF合成示意图

Fig. 3 LSPF composition diagram

目前LS的主要改性方法为酚化。Hu等

近年来,LSPF的应用成为研究领域的热点。付嘉

Cristina等

碱木质素(alkali lignin,AL)是由植物纤维原料的木质素在碱性化学试剂作用下,脱除并溶解在蒸煮液中,经加工、喷雾干燥后得到。AL资源丰富,是造纸行业的主要副产物之一,约占全球木质素总产量的85%,但理化性质变化大、结构复杂、稳定性差等因素限制了AL的广泛应用。目前,主要通过羟甲基化、脱甲基化和碱性酚化3种方法对AL进行活化,提高其反应活性,用于制备碱木质素基酚醛树脂(alkali lignin phenol-formaldehyde resin,ALPF)。

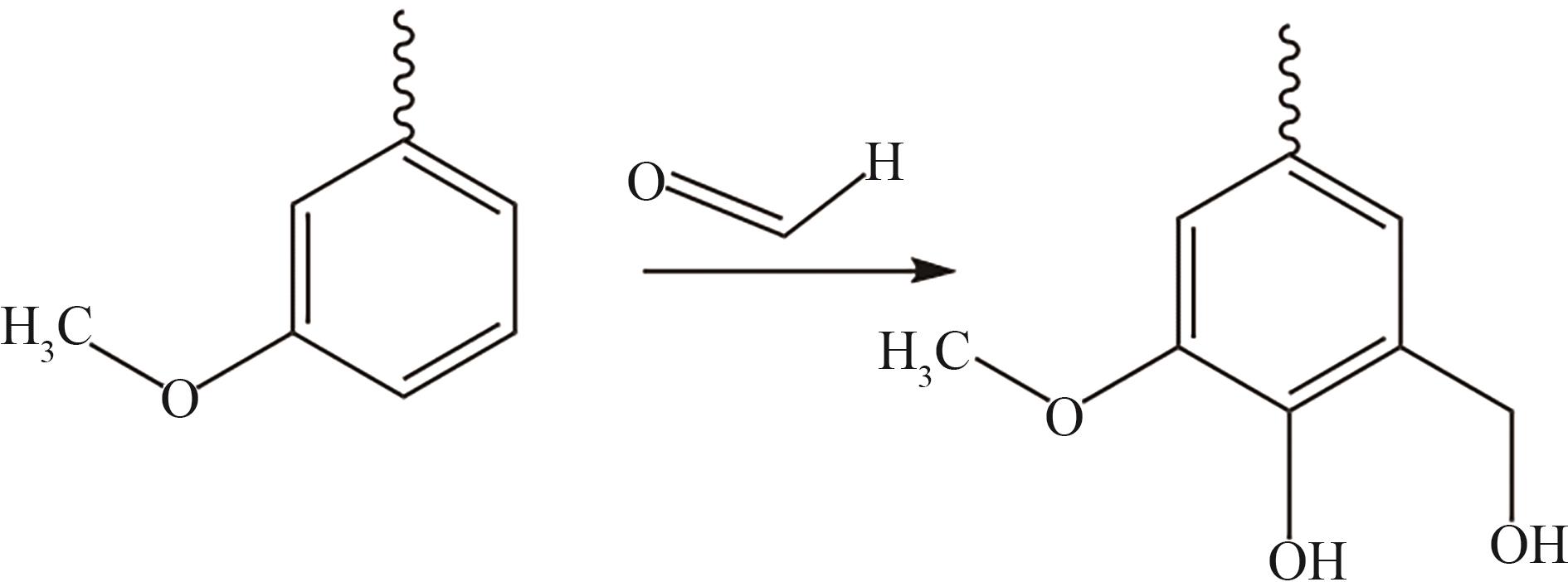

AL的羟甲基化改性是甲醛与AL在碱性条件下反应,生成活性更高的羟甲基化碱木质素(hydroxymethylated alkali lignin,HKLF),反应过程如

图 4 AL的羟甲基化反应

Fig. 4 Hydroxymethylation of alkali lignin

AL的脱甲氧基改性是将占据AL酚环活性位点上的甲氧基转变成酚羟基,使其反应活性位点增加。在低温常压条件下,利用亚硫酸钠作为脱甲基化试剂,对AL进行活化,制备高性能改性酚醛树脂胶黏剂。AL经过脱甲氧基化后反应活性增强,与未活化的木质素酚醛树脂相比,在固化速率、热稳定性、胶合强度、聚合度等方面都更具优越

AL的碱性酚化改性是AL在碱性高温条件下与苯酚发生化学反应,是制备ALPF最具应用潜力的方法。采用碱性酚化改性的方式可增加木质素反应活性位点含量,提高木质素酚醛树脂木材胶黏剂的反应活性,同时降低树脂中无机盐的含

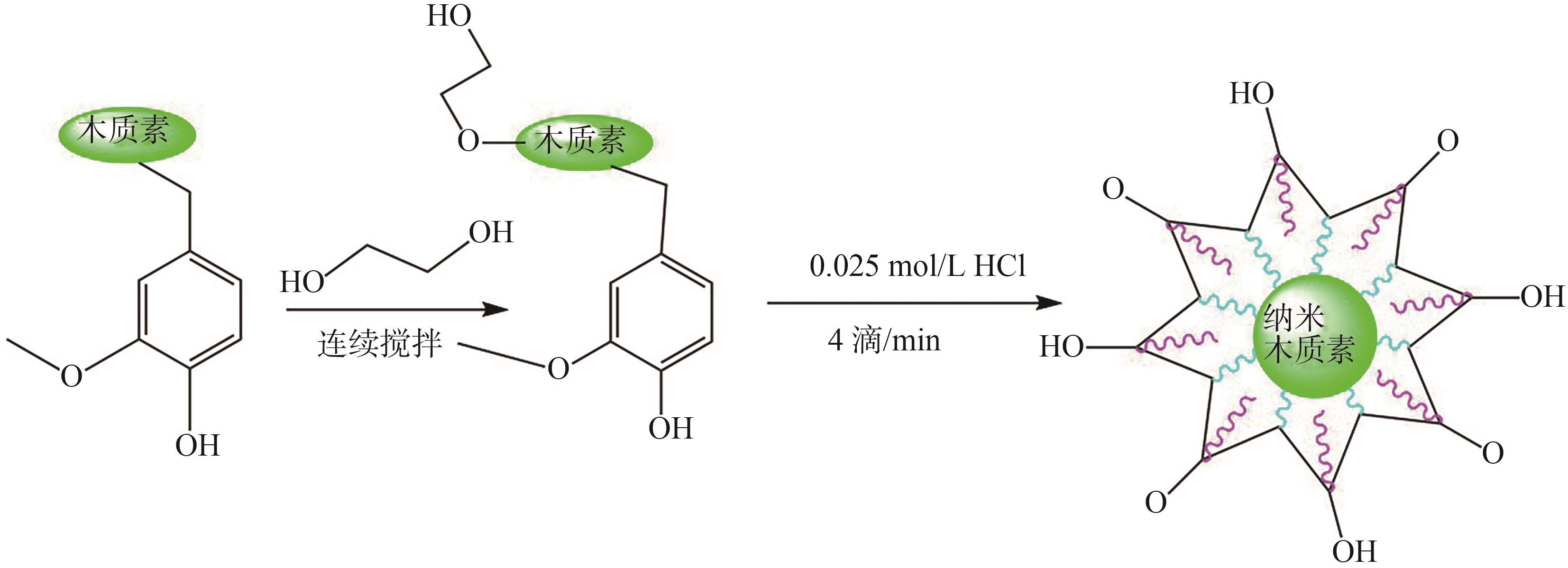

近年来,研究人员还提出多种新型改性方法对AL进行改性,并利用改性AL制备酚醛树脂。陈

图5 纳米木质素制备示意

Fig. 5 Diagram of the preparation of nano ligni

欧阳新平等

与含硫木质素相比,无硫木质素的结构与原始木质素的结构更相近,具有独特的化学性质,更容易生物降解,生物活性更高。无硫木质素无细胞毒性,具有优良的细胞抗氧化能力、清除自由基能力和抗糖尿病活性,更适用于化妆品、食品和药品等高价值应用领

酶解木质素(enzymatic hydrolysis lignin,EHL)是由木质纤维素类原料经酶解、发酵制备燃料丁醇或乙醇后剩下的残渣经分离、提纯后获得。相对其他种类木质素来说,由于EHL未经过高温、高压或强酸、强碱处理,结构保存较为完整,具有较多的活性基团,化学反应活性较

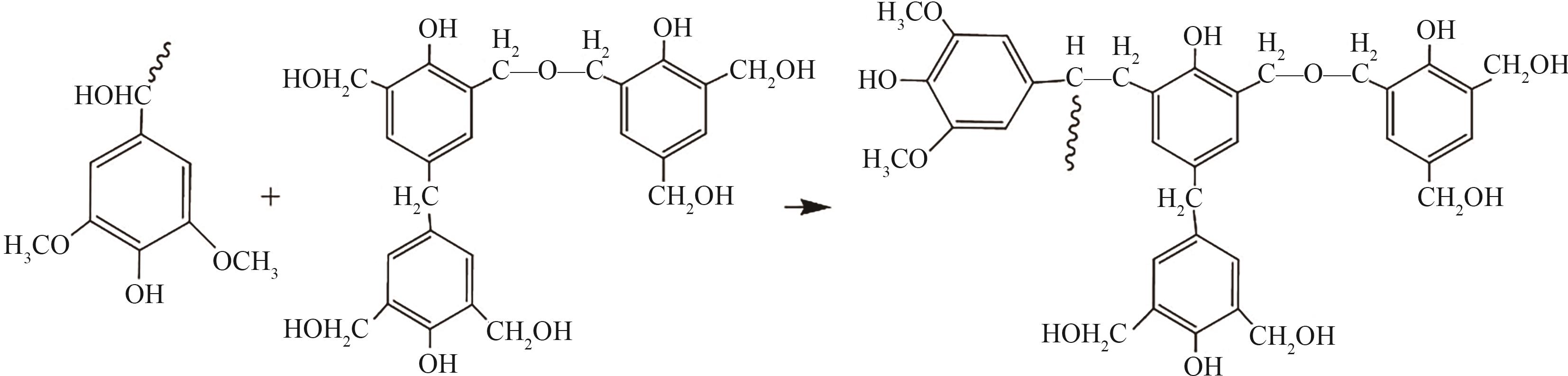

EHL代替苯酚制备酚醛树脂既可降低原料成本,又可改善酚醛树脂的性能,还能够充分利用EHL的价值。玉米秸秆提取出的EHL,可与酚醛树脂发生聚合反应,其反应过程如

图6 玉米秸秆提取出的EHL与酚醛树脂之间的聚合反

Fig. 6 Polymerization reaction between PF and EHL extracted from corn stra

周静等

EHLPF的开发利用不仅能够减轻生物质炼制行业的污染问题,是实现未来绿色化生产的重要途径;也减少了对石油化工副产品的依赖,缓解了产品危

有机溶剂制浆法是一种绿色环保、高得率并且具有较高纸浆强度的制浆方法,符合未来工业发展趋

木质素基酚醛树脂的制备与应用不仅可以使大量生物质资源得到高值化利用,还能有效地缓解环境污染、石油资源短缺等问题,符合当今世界可持续发展的要求。由于木质素结构复杂,不同种类木质素结构和性能有显著差异,目前木质素的价值未得到充分利用。木质素基酚醛树脂还存在甲醛含量较高、产品储存时间短、制备工艺复杂及产物性能改善不明显的问题,其还未大规模应用于生产。目前,木质素基酚醛树脂的制备与应用主要存在以下3方面问题。

(1)在木质素基酚醛树脂的制备中,当苯酚取代率足够高时,能够有效降低木质素基酚醛树脂中的甲醛含量,并且能够提高木质素基酚醛树脂的胶合强度。目前可通过2种方式提高苯酚取代率,一是通过酚化、液化、超声波活化等方法对木质素进行改性,二是选择对羟基、苯基含量较高的木质素作为主要原料,如从玉米秸秆提取的酶解木质素。

(2)探究并选择木质素的适宜用量,通过羟甲基化、碱性酚化及超声处理等方式对木质素进行改性,是延长木质素基酚醛树脂产品储存时间的关键。

(3)未来研究中可根据不同种类木质素的结构和性能,选择适宜的改性工艺与制备方式,最大程度地发挥其优良特性,并将研究集中于可工业化的木质素改性工艺与对木质素原料有针对性的酚醛树脂制备工艺上。

参 考 文 献

TANG K H, ZHANG A, GE T J, et al. Research Progress on Modification of Phenolic Resin[J]. Materials Today Communications, DOI:10.1016/j.mtcomm.2020.101879. [百度学术]

柴 瑜, 徐文彪, 时君友. 纤维素乙醇木质素改性酚醛树脂胶黏剂的初步研究[J].林产工业, 2015, 42(6): 38-40+54. [百度学术]

CAI Y, XU W B, SHI J Y. Preliminary Study on Phenolic Resin Adhesive Modified by Cellulose Ethanol Lignin[J]. China Forest Products Industry, 2015, 42(6): 38-40+54. [百度学术]

丁冬海, 杨少雨, 肖国庆. 含碳耐火材料酚醛树脂结合剂的研究现状与展望[J]. 材料导报, 2017, 31(11): 95-100. [百度学术]

DING D H, YANG S Y, XIAO G Q. Research Status and Prospect of Phenolic Resin Binder for Carbon Containing Refractories[J]. Materials Reports, 2017, 31(11): 95-100. [百度学术]

黄世俊, 童跃进, 苏志忠, 等. 木质素改性酚醛树脂的合成及其模塑料的性能[J]. 复合材料科学与工程, 2021, 11: 102-107. [百度学术]

HUANG S J, TONG Y J, SU Z Z, et al. Synthesis of Lignin Modified Phenolic Resin and Properties of Its Molding Compound[J]. Composites Science and Engineering, 2021, 11 : 102-107. [百度学术]

吴强林, 方红霞, 丁运生, 等. 木质素基酚醛树脂泡沫塑料的结构与性能研究[J]. 工程塑料应用, 2012, 40(11): 69-73. [百度学术]

WU Q L, FANG H X, DING Y S, et al. Study on Structure and Properties of Lignin Based Phenolic Resin Foam[J]. Engineering Plastics Application, 2012, 40(11): 69-73. [百度学术]

马文婷, 赵 敏, 孙均利. 绢云母填料对硼酚醛防火涂料的性能影响研究[J]. 消防科学与技术, 2020, 39(11): 1577-1580. [百度学术]

MA W T, ZHAO M, SHUN J L. Effect of Sericite Filler on Properties of Boron Phenolic Fire Retardant Coating[J]. Fire Science and Technology, 2020, 39(11): 1577-1580. [百度学术]

BYUN H Y, CHOI M H, CHUNG I J. Synthesis and Characterization of Resol Type Phenolic Resin/Layered Silicate Nanocomposites[J]. Chemistry of Materials, 2001, 13(11): 4221-4226. [百度学术]

SU W Y, HUI L F, MA X Y, et al. Preparation of High-precision Electrospun Nanoair Filter Paper for Air Purification[J]. Paper and Biomaterials, 2021, 6(4): 12-20. [百度学术]

MOUFEL C, GARNIER T, CASSAGNAU P, et al. Phenolic Foams: A Review of Mechanical Properties, Fire Resistance and New Trends in Phenol Substitution[J]. Polymer, 2019, 164: 86-117. [百度学术]

HAIFENG Z, DANDAN X, SHUAI Z, et al. Study on Improving the High-temperature Oxidation Resistance of Pyrolytic Carbons of Phenolic Resin Binder by In-situ Formation of Carbon Nanotubes[J]. Reactive and Functional Polymers, DOI:10.1016/j.reactfunctpolym.2020.104772. [百度学术]

PILATO L. Phenolic Resins: 100 Years and Still Going Strong[J]. Reactive and Funcational Polymers, 2013, 73(2): 270-277. [百度学术]

王一双, 陈明强, 史经经, 等. 载体对钼基催化剂催化解聚硫酸盐木质素制备液体燃料和酚类单体的影响研究(英文)[J]. 燃料化学学报, 2021, 49(12): 1922-1935. [百度学术]

WANG Y S, CHEN M Q, SHI J J, et al. Effect of Support on Preparation of Liquid Fuel and Phenolic Monomers by Catalytic Depolymerization of Sulfate Lignin with Molybdenum Based Catalyst (Einglish) [J]. Journal of Fuel Chemistry and Technology, 2021, 49(12): 1922-1935. [百度学术]

李鹏辉, 吴彩文, 刘 宸, 等. 木质素复合水凝胶性能及应用的研究进展[J]. 生物工程学报, 2022,38(7):2489-2498. [百度学术]

LI P H, WU C W, LIU C, et al. Research Progress in Properties and Application of Lignin Based Hydrogels[J]. Chinese Journal of Biotechnology, 2022,38(7):2489-2498. [百度学术]

宋剑斌, 周为明, 张明昕, 等. 木质素基燃料电池双极板的制备及性能研究[J]. 塑料工业, 2018, 46(3): 147-150+154. [百度学术]

SONG J B, ZHOU W M, ZHANG M X, et al. Preparation and Performance Study of Lignin Based Fuel Cell Bipolar Plate[J]. China Plastics Industry, 2018, 46(3): 147-150+154. [百度学术]

BEDIA J, ROSAS J M, RODRIGUEZ-MIRASOL J, et al. Pd Supported on Mesoporous Activated Carbons with High Oxidation Resistance as Catalysts for Toluene Oxidation[J]. Applied Catalysis B: Environmental, 2010, 94(1/2): 8-18. [百度学术]

胡立红, 周永红, 张 猛, 等. 木质素糠醛改性甲阶酚醛树脂的合成[J]. 热固性树脂, 2010, 25(3): 23-26. [百度学术]

HU L H, ZHOU Y H, ZHANG M, et al. Synthesis of Lignin Furfural Modified Methyl Phenolic Resin[J]. Thermosetting Resin, 2010, 25(3): 23-26. [百度学术]

周方浪, 郑志锋, 杨 静, 等. 木质素基酚醛树脂泡沫的制备及性能研究[J]. 林产化学与工业, 2018, 38(6): 103-109. [百度学术]

ZHOU F L, ZHENG Z F, YANG J, et al. Preparation and Properties of Lignin Based Phenolic Resin Foam[J]. Chemistry and Industry of Forest Products, 2018, 38(6): 103-109. [百度学术]

颉盼盼, 连海兰, 孙 香. 氯化胆碱/丙三醇低共熔离子液改性木质素酚醛树脂[J]. 林业工程学报, 2016, 1(4): 107-113. [百度学术]

XIE P P, LIAN H L, SUN X. Lignin Phenolic Resin Modified by Choline Chloride / Glycerol Eutectic Ionic Liquid[J]. Journal of Forestry Engineering, 2016, 1(4): 107-113. [百度学术]

胡 健, 杨 进, 詹怀宇, 等. 改性水溶性酚醛树脂的合成及在三滤纸中的应用[J]. 中国造纸, 2009, 28(4): 23-25. [百度学术]

HU J, YANG J, ZHAN H Y, et al. Synthesis of Modified Water Soluble Phenolic Resin and Its Application in Three Filter Paper[J]. China Pulp & Paper, 2009, 28(4): 23-25. [百度学术]

Li P, Zhou H, Tao Y, et al. Recent development and perspectives of solvents and electrode materials for electrochemical oxidative degradation of lignin[J]. Electroanalysis, DOI: 10.1002/elan.202200100. [百度学术]

PÉREZ P, TORO-LABBÉ A. Characterization of Keto-Enol Tautomerism of Acetyl Derivatives from the Analysis of Energy, Chemical Potential, and Hardness[J]. The Journal of Physical Chemistry A, 2000, 104(7): 1557-1562. [百度学术]

李鹏辉, 任建鹏, 吴文娟. 木质素在低共熔溶剂中降解的研究进展[J]. 中国造纸, 2022, 41(1): 78-85. [百度学术]

LI P H, REN J P, WU W J. Research Progress of Lignin Degradation in Deep Eutectic Solvents[J]. China Pulp & Paper, 2022, 41(1): 78-85. [百度学术]

POVEDA-GIRALDO J A, SOLARTE-TORO J C, ALZATE C A C, et al. The Potential Use of Lignin as a Platform Product in Biorefineries: A Review[J]. Renewable and Sustainable Energy Reviews, DOI:10.1016/j.rser.2020.110688. [百度学术]

靳艳巧, 张义转, 何洲峰, 等. 木质素液化多元醇改性酚醛树脂胶粘剂的合成与性能[J]. 高分子材料科学与工程, 2013, 29(5): 5-8. [百度学术]

JIN Y Q, ZHANG Y Z, HE Z F, et al. Synthesis and Properties of Phenolic Resin Adhesive Modified by Lignin Liquefied Polyol[J]. Polymer Materials Science & Engineering, 2013, 29(5): 5-8. [百度学术]

Lu W M, Li Q, Zhang Y, et al. Lignosulfonate/APP IFR and Its Flame Retardancy in Lignosulfonate-based Rigid Polyurethane Foams[J]. Journal of Wood Science, 2018, 64(3): 287-293. [百度学术]

YAMAMOTO K, HOSOYA T, YOSHIOKA K, et al. Tetrabutylammonium Hydroxide 30-Hydrate as Novel Reaction Medium for Lignin Conversion[J]. ACS Sustainable Chemistry & Engineering, 2017, 9(5): 10111-10115. [百度学术]

CHEN K, GAO M D, DING C, et al. A Green Approach for the Synthesis of Novel Ag3PO4/SnO2/Porcine Bone and Its Exploitation as a Catalyst in the Photodegradation of Lignosulfonate into Alkyl Acids[J]. RSC Advances, 2018, 8(47): 26782-26792. [百度学术]

严振宇, 魏录录, 邓拥军, 等. 硫酸盐木质素的分级分离及性能比较[J]. 应用化工, 2020, 49(7): 1626-1629. [百度学术]

YAN Z Y, WEI L L, DENG Y J, et al. Fractionation and Performance Comparison of Lignin Sulfate[J]. Applied Chemical Industry, 2020, 49(7): 1626-1629. [百度学术]

FERNANDO D O, CRISTINA GOMES D S, LUIZ R, et al. Phenolic and Lignosulfonate-based Matrices Reinforced with Untreated and Lignosulfonate-treated Sisal Fibers[J]. Industrial Crops and Products, 2017, 9(6): 30-41. [百度学术]

HU L H, ZHOU J, BO C Y,et al. Physicochemical Characterization of Oxidatively Degraded Calcium Lignosulfonate via Alkaline Hydrogen Peroxide[Z]. Advanced Materials Research, 2014, 887/888: 575-580. [百度学术]

LUO M, LI Y, SHAO B S, et al. In Situ Formation of Carbon Nanotubes and Ceramic Whiskers in Al2O3-C Refractories with Addition of Ni-catalyzed Phenolic Resin[J]. Materials Science & Engineering A, 2012, 558: 533-542. [百度学术]

INOMATA K, OTAAKETAKE Y. Formation and Development of Micropores in Carbon Prepared Via Catalytic Carbonization of Phenolic Resin Containing Fe or Ni Compouds[J]. Microporous and Mesoporous Materials, 2011, 143(1): 60-65. [百度学术]

方 伟, 赵 雷, 梁 峰, 等. 硝酸镍复合木质素改性酚醛树脂的热解炭结构演变[J]. 新型炭材料, 2015, 30(4): 327-334. [百度学术]

FANG W, ZHAO L, LIANG F, et al. Structural Evolution of Pyrolytic Carbon with Nickel Nitrate Composite Lignin Modified Phenolic Resin[J]. New Carbon Materials, 2015, 30(4): 327-334. [百度学术]

HU L H, ZHOU Y H, LIU R J, et al. Synthesis of Foaming Resol Resin Modified with Oxidatively Degraded Lignosulfonate[J]. Industrial Crops and Products, 2013, 44: 364-366. [百度学术]

付嘉豪. 木质素基酚醛微球的合成及性能研究[D]. 北京: 北京化工大学, 2020. [百度学术]

FU J H. Synthesis and Properties of Lignostin-based Phenolic Microspheres[D]. Beijing: Beijing University of Chemical Technology, 2020. [百度学术]

来冰冰. 基于廉价载体后修饰法固载铜配合物催化剂制备及其应用研究[D].武汉: 华中科技大学, 2019. [百度学术]

LAI B B. Preparation and Application of Copper Complex Catalysts by Inexpensive Post-modified Support Method[D]. Wuhan: Huazhong University of Science and Technology, 2019. [百度学术]

CRISTINA D S G, FERNANDO O R, CRISTINA R E, et al. Composites from a Forest Biorefinery Byproduct and Agrofibers: Lignosulfonate-phenolic Type Matrices Reinforced with Sisal Fibers[J]. Tappi Journal, 2012, 11(9): 41-49. [百度学术]

TANG H, LI N, LI G G, et al. Dehydration of Carbohydrates to 5-Hydroxymethylfurfural over Lignosulfonate-based Acidic Resin[J]. Sustainable Chemistry & Engineering, 2018, 6(4): 5645-5652. [百度学术]

THEBAULT M, LI Y, BEUC C, et al. Impregnated Paper-based Decorative Laminates Prepared from Lignin-substituted Phenolic Resins[J]. Journal of Rrenwable Materials, 2020, 8(10): 1181-1198. [百度学术]

VIKTOR S, PETAR A. Engineering the Properties of Eco-friendly Medium Density Fibreboards Bonded with Lignosulfonate Adhesive[J]. Drvna Industrija, 2020, 71(2): 157-162. [百度学术]

LUKASZ K, ARTUR J, BEATA S, et al. Activation of Magnesium Lignosulfonate and Kraft Lignin: Influence on the Properties of Phenolic Resin-based Composites for Potential Applications in Abrasive Materials[J]. International Journal of Molecular Sciences, 2017, 18(6): 1224-1242. [百度学术]

李炯炯. 木质素活化及改性酚醛树脂制备与固化胶接机制研究[D]. 北京: 北京林业大学, 2019. [百度学术]

LI J J. Study on Preparation and Curing Bonding Mechanism of Lignin Activated and Modified Phenolic Resin[D]. Beijing: Beijing Forestry University, 2019. [百度学术]

庄晓伟, 穆有炳, 潘 炘, 等. 碱木质素-酚醛复合胶黏剂在竹胶板中的应用研究[J]. 生物质化学工程, 2011, 45(5): 17-20. [百度学术]

ZHUANG X W, MU Y B, PAN X, et al. Application of Alkali Lignin Phenolic Composite Adhesive in Bamboo Plywood[J]. Biomass Chemical Engineering, 2011, 45(5): 17-20. [百度学术]

李立霞. 多级孔分子筛负载铜基催化剂的制备及其催化木质素选择性氧化解聚[D]. 广州: 华南理工大学, 2020. [百度学术]

LI L X. Preparation of Copper Based Catalyst Supported on Multi-stage Porous Molecular Sieve and its Catalytic Effect on Selective Oxidative Depolymerization of Lignin[D]. Guangzhou: South China University of Technology, 2020. [百度学术]

蹇均宇, 高士帅, 张代晖, 等. 碱性酚化木质素结构表征及在酚醛树脂中的应用研究[J]. 中国胶粘剂, 2021, 30(5): 21-24+30. [百度学术]

JIAN J Y, GAO S S, ZHANG D H, et al. Structural Characterization of Alkaline Phenolic Lignin and its Application in Phenolic Resin[J]. China Adhesives, 2021, 30(5): 21-24+30. [百度学术]

陈 宇. 木质素酚醛树脂复合胶黏剂的纳米改性及其性能研究[D]. 石河子: 石河子大学, 2020. [百度学术]

CHEN Y. Study on Nano Modification and Properties of Lignin Phenolic Resin Composite Adhesive[D]. Shihezi: Shihezi University, 2020. [百度学术]

欧阳新平, 林再雄, 邓永红, 等. 碱木质素的微波氧化降解[J]. 化学物理学报(英文版). 2010, 18(4): 695-702. [百度学术]

OUYANG X P, LIN Z X, DENG Y H, et al. Microwave Oxidative Degradation of Alkali Lignin [J]. Chinese Journal of Chemical Engineering(English Version) 2010, 18(4): 695-702. [百度学术]

李腾飞, 武书彬, 庄军平, 等. 氧化预处理木质素制备高性能木质素酚醛树脂胶粘剂[J]. 应用化工, 2022, 51(4): 907-911. [百度学术]

LI T F, WU S B, ZHUANG J P, et al. Preparation of High Performance Lignin Phenolic Resin Adhesive by Chemical Pretreatment of Lignin[J]. Applied Chemical Industry, 2022, 51(4): 907-911. [百度学术]

程明娟, 连海兰, 李 涛. 超声波法活化麦草碱木素及用于PF胶黏剂的研究[J]. 林产工业, 2012, 39(2): 31-34+40. [百度学术]

CHENG M J, LIAN H L, LI T. Study on Ultrasonic Activation of Wheat Straw Alkali Lignin and Its Application in PF Adhesive[J]. China Forest Products Industry, 2012, 39(2): 31-34+40. [百度学术]

杨 伟, 李 追, 毕严文, 等. 聚丙烯酸接枝碱木质素/酚醛开孔吸水材料的工艺研究[J]. 生物质化学工程, 2015, 49(3): 7-12. [百度学术]

YANG W, LI Z, BI Y W, et al. Study on the Technology of Polyacrylic Acid Grafted Alkali Lignin / Phenolic Porous Water Absorbing Material[J]. Biomass Chemical Engineering, 2015, 49(3): 7-12. [百度学术]

ZHANG J, LIANG J K, DU G B, et al. Performance of Cutting and Grinding Wheel Based on Lignin-Phenolic Resin Matrix and Aluminum Oxide[J]. Bioresources, 2017, 12(4): 9118-9129. [百度学术]

GIL-CHÁVEZ G J, PADHI S S P, PEREIRA C V, et al. Cytotoxicity and Biological Capacity of Sulfur-free Lignins Obtained in Novel Biorefining Process[J]. International Journal of Biological Macromolecules, 2019, 136(1): 697-703. [百度学术]

RUMPF J, DO X T, BURGER R, et al. Extraction of High-purity Lignins via Catalyst-free Organosolv Pulping from Low-input Crops[J]. BioMacromolecules, 2020, 21(5): 1929-1942. [百度学术]

刘贤淼, 张俊逸, 张 波, 等. 制浆黑液成分及蒸发特性研究[J]. 中国造纸学报, 2018, 33(2): 35-39. [百度学术]

LIU X M, ZHANG J Y, ZHANG B, et al. Study on Composition and Evaporation Characteristics of Pulping Black Liquor[J]. Transactions of China Pulp and Paper, 2018, 33(2): 35-39. [百度学术]

FENG S H, SHUI T, WANG H Y, et al. Properties of Phenolic Adhesives Formulated with Activated Organosolv Lignin Derived from Cornstalk[J]. Industrial Crops and Products, DOI:10.1016/j.indcrop.2020.113225. [百度学术]

SOMAYYEH K, CHEN N S, HAMID B, et al. Omparative Analysis of Different Lignins as Phenol Replacement in Phenolic Adhesive Formulations[J]. International Journal of Molecular Sciences, 2018, 125: 520-528. [百度学术]

周 静, 胡立红, 周永红, 等. 酶解木质素液化降解制备酚醛树脂用酚类化合物的研究[J]. 工程塑料应用, 2014, 42(2): 101-106. [百度学术]

ZHOU J, HU L H, ZHOU Y H, et al. Study on the Preparation of Phenolic Compounds for Phenolic Resins by Enzymatic Lignin Liquefaction Degradation[J]. Engineering Plastics Application, 2014, 42(2): 101-106. [百度学术]

周 静, 胡立红, 周永红, 等. 酶解木质素基酚醛模塑料的制备及性能研究[J]. 化工新型材料, 2018, 46(4): 78-81. [百度学术]

ZHOU J, HU L H, ZHOU Y H, et al. Preparation and Properties of Enzymaticlyzed Lignin-based Phenolic Molding Compounds[J]. New Chemical Materials, 2018, 46(4): 78-81. [百度学术]

罗雄飞, 李新生, 王哲东, 等. 超声活化酶解木质素用于酚醛树脂的制备[J].森林工程, 2017, 33(3): 39-43. [百度学术]

LUO X F, LI X S, WANG Z D, et al. Ultrasonic Activation Enzymatic Lignin for the Preparation of Phenolic Resin[J]. Forest Engineering, 2017, 33(3): 39-43. [百度学术]

郝 臣, 张鹏飞, 谢文静, 等. 超声作用对木质素胺化改性的影响[J]. 中国造纸学报, 2012, 27(1): 50-53. [百度学术]

HAO C, ZHANG P F, XIE W J, et al. Effect of Ultrasound on Amination Modification of Lignin[J]. Transactions of China Pulp and Paper, 2012, 27(1): 50-53. [百度学术]

李淑君, 杨冬梅, 韩世岩,等. 酶解木质素基酚醛树脂的合成及应用研究[R].哈尔滨: 东北林业大学, 2017. [百度学术]

LI S J, YANG D M, HAN S Y,et al. Synthesis and Application of Enzymatic Lignin-based Phenolic Resin[R]. Harbin: Northeast Forestry University, 2017. [百度学术]

王祺铭, 海潇涵, 时君友, 等. 新型酶解木质素酚醛泡沫的制备及性能研究[J]. 林产工业, 2020, 57(3): 35-40. [百度学术]

WANG Q M, HAI X H, SHI J Y, et al. Preparation and Performance of Novel Enzymaticlyzed Lignosu Phenolic Foam[J]. Forest Products Industry, 2020, 57(3): 35-40. [百度学术]

赵丽斌, 冯利邦, 易增博, 等. 酶解木质素改性酚醛泡沫塑料的制备与性能[J]. 高分子材料科学与工程, 2015, 31(3): 138-141. [百度学术]

ZHAO L B, FENG L B, YI Z B, et al. Preparation and Properties of Enzymaticlyzed Lignin-modified Phenolic Foam[J]. Polymer Materials Science & Engineering, 2015, 31(3): 138-141. [百度学术]

陈艳艳, 常 杰, 范 娟. 秸秆酶解木质素制备木材胶黏剂工艺[J]. 化工进展, 2011, 30(S1): 306-312. [百度学术]

CHEN Y Y, CHANG J, FAN J. Process of Preparing Wood Adhesive by Straw Enzymatic Lysis of Lignin[J]. Chemical Industry and Engineering Progress, 2011, 30(S1): 306-312. [百度学术]

LI P, REN J, JIANG Z, et al. Review on the Preparation of Fuels and Chemicals Based on Lignin[J]. RSC Advances, 2022, 12: 10289-10305. [百度学术]

KOSKELA H, KILPELÄINEN I, HEIKKINEN S, et al. Some Aspects of Quantitative 2D NMR[J]. Journal of Quantitative Msgnentic Resonance, 2005, 174(2): 237-244. [百度学术]

HUSSIN M H, SAMAD N A, LATIF N H A, et al. Production of Oil Palm (Elaeis Guineensis) Fronds Lignin-derived Non-toxic Aldehyde for Eco-friendly Wood Adhesive[J]. International Journal of Biological Macromoliecules, 2018, 113: 1266-1272. CPP [百度学术]