摘要

再生资源高效利用是生态文明建设的重要方式。回用纤维以其低消耗、低污染的优点,近年来在制浆造纸行业中受到广泛关注。本文简述了回用纤维在生活用纸中应用存在的问题及解决措施,展望了回用纤维在生产生活用纸中的发展前景。

生活用纸是日常生活中用于卫生或清洁的纸制品,包括但不限于卫生纸、餐巾纸、面巾纸、厨房用纸等。这些产品以其方便、卫生的特性成为不可或缺的一部分。生活用纸的质量、实用性和生产方式对环境、资源的可持续发展和利用,以及人类生活的舒适度和健康有着直接的影

近年来,我国生活用纸市场保持持续增长,产能、产量、消费量、人均消费量等均实现了较高的年均复合增长。据文献报

生活用纸是造纸行业中的三大纸制品之一。生活用纸原料的发展反映了人类对环境保护、资源可持续利用,以及产量质量提升的不断追求。最初,生活用纸主要采用原生木浆为原料。然而,随着环境保护意识的增强和对森林资源的保护,人们开始寻求更多的替代纤维,以减少对自然森林的破坏;之后非木材纤维被发掘和应用,包括竹浆、稻草、甘蔗

回用纤维的回用,即利用回收的废纸生产新的纸张,是当前纸制品行业节约资源的重要策略。尽管回用纤维的使用带来了显著的环境和经济效益,但其回用过程面临着一系列问题和挑

在生活用纸的制造过程中,部分厂家为了降低生产成本,大量使用回用纤维。如美国Cascades使用纸板生产出浅色系生活用

回用纤维回收再利用的主要问题是纤维角质化。角质化是指在经历反复润胀-干燥过程后,纤维发生不可逆变化的过

在回用纤维中,混合办公废纸因其数量大、质量好、价格低而备受欢

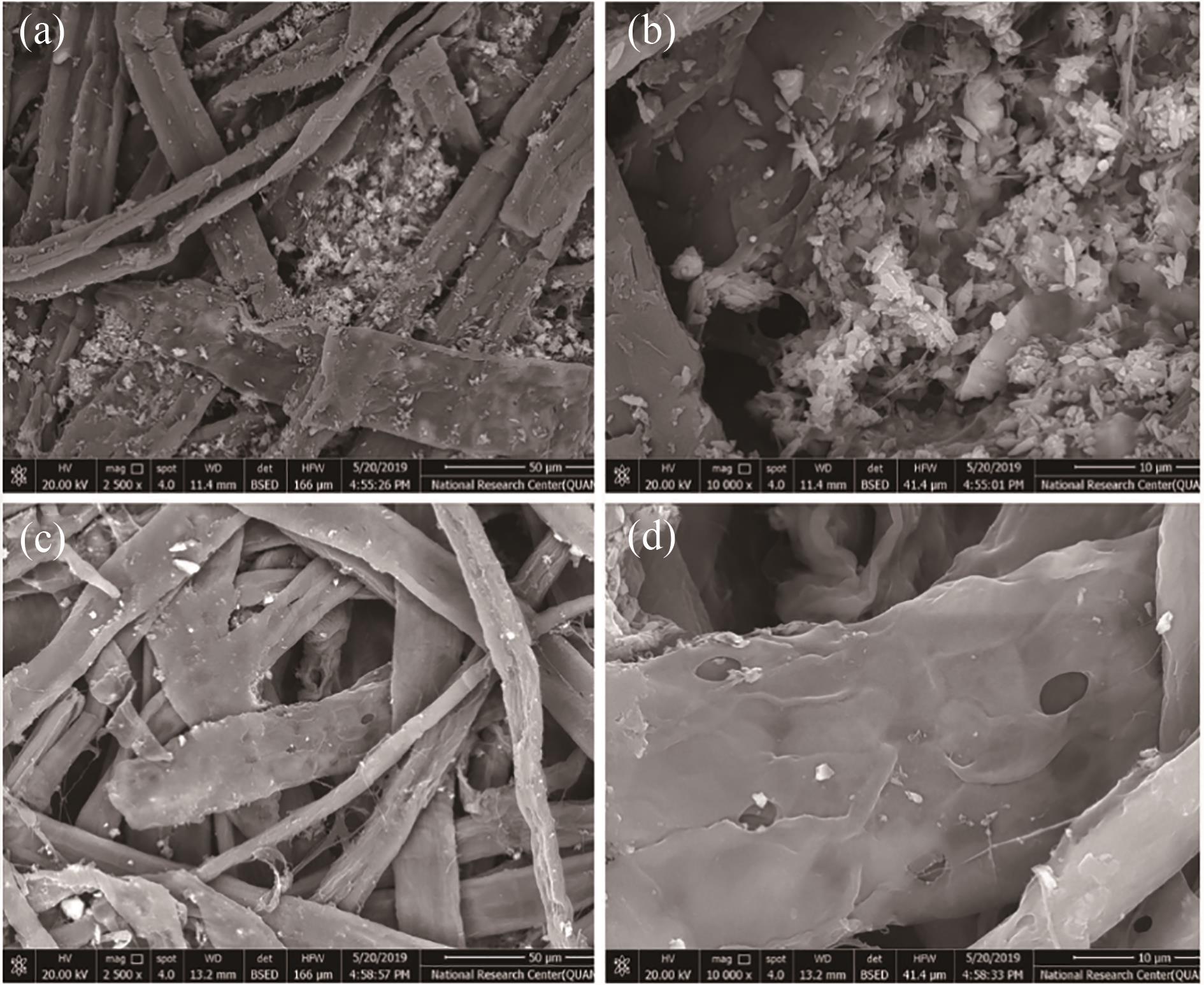

图 1 SEM图:未脱墨(a)(b)和经过脱墨处理(c)(d)的纸浆

Fig. 1 SEM images of pulps: (a) (b) undeinking; (c) (d) deinking

随着人们生活水平的提高,生活用纸的需求不断增加,对生活用纸产品的质量和性能要求也越来越高。因此,无论是用植物纤维还是回用纤维生产的生活用纸,保证产品质量是制造商面临的重要挑战。本文主要从柔软度、吸水性、强度

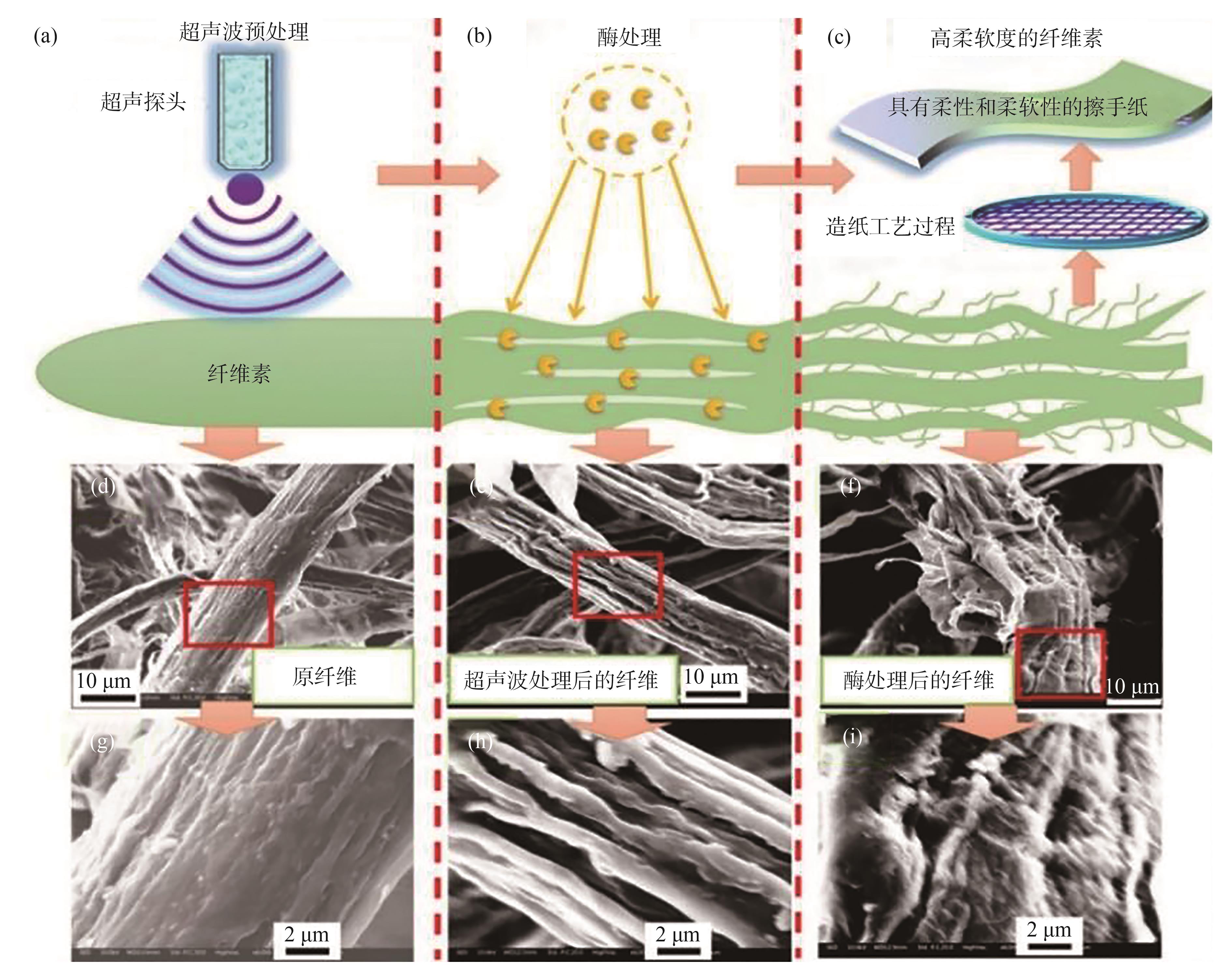

柔软度通常被视为衡量生活用纸质量的关键指标,也是生活用纸产品的关键消费属性。目前,提高柔软度的方法主要包括起皱、调整纤维配比、添加柔软剂、生物酶处理

起皱技

图 2 超声波辅助纤维素酶处理对竹浆纤维的作用原

Fig. 2 Principle analysis of bamboo pulp fiber treated with ultrasonic action assisted cellulas

另外,造纸生产过程中还可以通过添加柔软剂来提高柔软度。柔软剂的使用方式主要有浆内添加和表面喷涂2

使用生活用纸时有时面临潮湿环境,所以吸水性也是其重要的指标之一,也会成为消费者选择的差异化因素。生活用纸的吸水性主要取决于所用纤维的吸水性能和纤维之间的孔隙

压花是通过施加局部压力对原纸表面进行变形,增加生活用纸的厚度和体积,来提升吸水性的方法。孙海

合理控制打浆度也可以改善生活用纸的吸水性能。打浆使纤维中的羟基暴露,增大细纤维化程度和纤维分丝帚化程度,使纤维更易横向切断,产生更多新的纤维壁腔端口,对胞腔通过毛细管力吸水产生一定的积极作用,从而提升纤维的吸水

在造纸生产中,荧光增白剂被广泛用作添加剂以改善纸产品的白度。荧光增白剂是一种有毒致癌物质,用含有荧光增白剂的废纸生产生活用纸,会危害人体健

为应对气候变化,世界各国纷纷制定“碳中和”时间表,这意味着世界各国将加大对森林的保护,减少树木的砍伐。低碳循环绿色生产将是生活用纸制造业发展的必由之

生活用纸作为日常生活中的必需品,在激烈的市场竞争中,不断改善生产方式和提高商品质量是企业需要充分考虑的。回用纤维在生活用纸中的应用具有重要的时代意义和实际价值。但随着国家双碳目标发展战略的推进,传统植物纤维的利用也面临着从生态和技术上的双重挑战,使用回用纤维在生活用纸生产中的应用虽然具有充分的可行性,但仍需要对改善回用纤维品质方面进行更深刻的研究,来保证回用纤维的性能、产品的质量和经济效益。同时,随着可持续发展理念的深入人心,未来生活用纸企业需要更加坚定不移地追求技术进步和科技创新,不断改进和优化生活用纸生产工艺的新技术新方法,将回用纤维升级为适用于生活用纸制造的高质量纸浆,不仅满足市场对生活用纸的需求,并且实现生活用纸的绿色转型和高质量发展。

参 考 文 献

周 杨. 中国生活用纸市场发展概况和趋势分析[J]. 中国造纸学报, 2022, 37(S1): 222-226. [百度学术]

ZHOU Y. Development Overview and Trend Analysis of China’s Household Paper Market[J]. Transactions of China Pulp and Paper, 2022, 37(S1): 222-226. [百度学术]

原生纤维和再生纤维:谁是更可持续的选择?[J]. 中华纸业, 2023,44(14): 75-76. [百度学术]

Primary Fiber and Regenerated Fiber: Who is the More Sustainable Choice?[J]. China Pulp & Paper Industry, 2023,44(14): 75-76. [百度学术]

万金泉.增加原料有效供给、提升废纸纤维品质的前沿技术[J]. 中华纸业, 2019, 40(23): 26-33. [百度学术]

WAN J Q. Cutting-edge Technology to Increase the Effective use of Raw Materials and Improve Wastepaper Fibers[J]. China Pulp & Paper Industry, 2019, 40(23): 26-33. [百度学术]

Northwood推出Whisper Green系列100%可再生卫生纸[J]. 中华纸业, 2021, 42(24): 69. [百度学术]

Northwood Launches the Whisper Green Range of 100% Renewable Toilet Paper[J]. China Pulp & Paper Industry, 2021,42(24):69. [百度学术]

牛继承, 李 力, 刘 剑. 利用废纸脱墨浆生产文化用纸[J]. 中华纸业, 2000,20(7): 39-40. [百度学术]

NIU J C, LI L, LIU J. Using Deinked Pulp from Waste Paper to Produce Cultural Paper[J]. China Pulp & Paper Industry, 2000, 20(7): 39-40. [百度学术]

TIAGO D A, JOEL P, LOKENDRA P, et al. Comparison of Wood and Non-wood Market Pulps for Tissue Paper Application[J]. Bioresources, 2019, 14(3): 6781-6819. [百度学术]

EI-SAYED A S E, EI-SAKHAWY M, EI-SAKHAWY A M. Non-Wood Fibers as Raw Material for Pulp and Paper Industry[J]. Nordic Pulp Paper Research Journal, 2020, 35(2): 215-230. [百度学术]

ZHANG Y, HAN Y L, YI M. Sustainability Evaluation of Tissue Paper under Different Production Paths[J]. ACS Sustainable Chemistry Engineering, 2021, 9(21): 7341-7351. [百度学术]

MASTERNAK-JANUS A, RYBACEWSKA-B M. Life Cycle Analysis of Tissue Paper Manufacturing from Virgin Pulp or Recycled Waste Paper[J]. Management and Production Engineering Review, 2015, 6(3):47-54. [百度学术]

DEBANTH M, SALEM S K, NAITHANI V, et al. Soft mechanical treatments of recycled fibers using a high-shear homogenizer for tissue and hygiene products[J]. Cellulose, 2021, 28(12): 1-14. [百度学术]

KUMAR A, DUTT D. A Comparative Study of Conventional Chemical Deinking and Environment-friendly Bio-deinking of Mixed Office Wastepaper[J]. Scientific African, DOI: 10. 1016/j. sciaf. 2021. E00793. [百度学术]

陈杨梅. 再生植物纤维循环回用过程中纤维角质化机理及纤维性能改性研究[D]. 广州: 华南理工大学, 2012. [百度学术]

CHEN Y M. The Mechanism of Fiber Hornification of Recycled Plant Fiber During Recycling and Modification of Fiber Properties[D]. Guangzhou: South China University of Technology, 2012. [百度学术]

BAJPAI P K. Solving the Problems of Recycled Fiber Processing with Enzymes[J]. BioResources, 2010, 5(2): 1-15. [百度学术]

美国Cascades使用再生纸和纸板生产浅色系生活用纸, 部分替代白色生活用纸产品[J]. 中华纸业, 2019, 40(10): 78. [百度学术]

Cascades USA Uses Recycled Paper and Paperboard to Produce Light-colored Tissue Products, Partially Relacing White Tissue Products[J]. China Pulp & Paper Industry, 2019, 40(10): 78. [百度学术]

法国WEPA集团引入新型生活用纸纤维原料[J]. 纸和造纸, 2023, 42(2): 63-63. [百度学术]

French WEPA Group Introduced a New Type of Household Paper Fiber Raw Materials[J]. Paper & Paper Making, 2023, 42(2): 63-63. [百度学术]

MO W X, CHEN K F, YANG X, et al. Elucidating the Hornification Mechanism of Cellulosic Fibers During the Process of Thermal Drying[J]. Carbohydrate Polymers, DOI:10.1016/j. carbpol. 2022.119434. [百度学术]

ZAMBRANO F, MARQUEZ R, VERA R, et al. Developing Alternative, High-absorbency Brown Fibers: Tissue Paper from Upcycled Corrugated Packaging Waste to Meet New Consumer Trends[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(40): 13343-13356. [百度学术]

ZAMBRANO F, MARQUEZ R, JAMEEL H, et al. Upcycling Strategies for Old Corrugated Containerboard to Attain High-performance Tissue Paper: A Viable Answer to the Packaging Waste Generation Dilemma[J]. Resources, Conservation & Recycling, DOI: 10. 1016/j. resconrec. 2021. 105854. [百度学术]

HASANIN S M, HASANIN H A, El-SAYED A S E, et al. Green Ecofriendly Bio-deinking of Mixed Office Waste Paper Using Various Enzymes from Rhizopus microsporus AH3: Efficiency and Characteristics[J]. Cellulose, 2020, 27(8): 1-11. [百度学术]

KUMAR N V, RANI M E, GUNASEELI R, et al. Paper Pulp Modification and Deinking Efficiency of Cellulase-Xylanase Complex from Escherichia Coli SD5[J]. International Journal of Biological Macromolecules, 2018, 111: 289-295. [百度学术]

张中山, 杨桂花, 裴丽华, 等. 超声处理对激光打印废纸脱墨效果的影响[J]. 纸和造纸, 2016, 35(4): 8-11. [百度学术]

ZHANG Z S, YANG G H, PEI L H, et al. Influence of Ultrasonic Treatment on the Deinking Effect of Laser Printing Waste Paper[J]. Paper & Paper Making, 2016, 35(4): 8-11. [百度学术]

WU S, CHEN S, ZHAO Y. Evaluation and Optimization of Old Magzines Deinking Process of a Modified Lignin Sulfonates Deinking Agent[J]. Paper and Biomaterials, 2019, 4(1): 31-39. [百度学术]

ABUBAKR S M, SCOTT G M, KLUNGNESS J H. Fiber Fractionation as a Method of Improving Hand Sheet Properties after Repeated Recycling[J]. Tappi Journal, 1995, 78(5): 123-126. [百度学术]

PAGE D H, SETH R H, JORDAN B D, et al. Curl, Crimps, Kinds and Micro Compressions in Pulp Fibers Their Origin, Measurement and Significance[M]. Oxford:Mechanical Engineering Publications Limited, 1985: 183-227. [百度学术]

管 敏, 李晨曦, 刘洪斌. 影响生活用纸柔软度主要因素的研究进展[J]. 中国造纸, 2018, 37(2): 58-65. [百度学术]

GUN M, LI C X, LIU H B. Review on the Key Factors Affecting Softness of Tissue Paper[J]. China Pulp & Paper, 2018, 37(2) :58-65. [百度学术]

LIU J, HU H R, XU J F, et al. Optimizing Enzymatic Pretreatment of Recycied Fiber to Improve its Draining Ability Using Response Surface Methodology[J]. Bioresources, 2012, 7(2): 2121-2140. [百度学术]

QIN T, LIU L Q, CAO H B. et al. Creping Technology and Its Factors for Tissue Paper Production: A Review[J]. European Journal of Wood and Wood Products, 2023, 81(5):1075-1091. [百度学术]

张方东, 曹海兵, 刘 晶, 等. 纤维素酶处理改善生活用纸柔软度等性能的研究[J]. 中国造纸, 2020, 39(3): 44-50. [百度学术]

ZHANG F D, CAO H B, LIU J, et al. Study on Cellulase Treatment for Improving the Softness and Other Properties of Tissue Paper[J]. China Pulp & Paper, 2020, 39(3): 44-50. [百度学术]

刘 晶. 超声波辅助纤维素酶处理提高竹浆纤维柔软度的研究[D]. 天津: 天津科技大学, 2019. [百度学术]

LIU J. Ultrasonication Assited Cellulase Treatment to Improve the Softness of Bamboo Pulp Fibers[D]. Tianjin: Tianjin University of Science and Technology, 2019. [百度学术]

AN X Y, ZHANG R Q, LIU L Q, et al. Ozone Pretreatment Facilitating Cellulase Hydrolysis of Unbleached Bamboo Pulp for Improved Fiber Flexibility[J]. Industrial Crops & Products, DOI: 10. 1016/j. indcrop. 2022. 114577. [百度学术]

PARK J Y, MELANI L, LEE H. Effect of Chemical Additives on Softness Components of Hygiene Paper[J]. Nordic Pulp & Paper Research Journal, 2019, 34(2): 172-181. [百度学术]

杨勤武, 杨益琴. 不同阳离子柔软剂对生活用纸性能的影响[J]. 纤维素科学与技术, 2015, 23(1): 66-70. [百度学术]

YANG Q W, YANG Y Q. Effect of Different Cationic Softening Agents on Household Paper[J]. Journal of Cellulose Science and Technology, 2015, 23(1): 66-70. [百度学术]

JOEKAR-NIASAR V, HASSANIZADEH S M. Effect of Initial Hydraulic Conditions on Capillary Rise in a Porous Medium: Pore‐Network Modeling[J]. Vadose Zone Journal,2012, 11(3): 215-228 [百度学术]

ASSIS T D, PAWLAK J, PAL L, et al. Comparison Between Uncreped and Creped Handsheets on Tissue Paper Properties Using a Creping Simulator Unit[J]. Cellulose, 2020, 27(10): 5981-5999. [百度学术]

孙海瑜. 一种高性能的S型压花厨房用纸: 103835188. 2[P]. 2014-06-04. [百度学术]

SUN H Y. A High-Performance S-shaped Embossed Kitchen Paper: 103835188. 2[P]. 2014-06-04. [百度学术]

VIEIRA J C, DE OLIVERIRA MENDES A, CARTA A M, et al. Impact of Embossing on Liquid Absorption of Toilet Tissue Papers[J]. BioResources, 2020, 15(2): 3888-3898. [百度学术]

张志鹏, 董奎斌, 李晨曦, 等. 影响生活用纸吸收性能的因素[J]. 中国造纸, 2022, 41(6): 89-94. [百度学术]

ZHANG Z P, DONG K B, LI C X, et al. Factors Affecting the Absorption Performance of Tissue Paper[J]. China Pulp & Paper, 2022, 41(6): 89-94. [百度学术]

史海真, 刘 文, 史 贺, 等. 打浆方式对生活用纸未起皱原纸性能的影响[J]. 中华纸业, 2016, 37(8): 51-57. [百度学术]

SHI H Z, LIU W, SHI H, et al. Influence of Beating Mode on Properties of Non-wrinkle base Paper for Household Paper[J]. China Pulp & Paper Industry, 2016, 37(8): 51-57. [百度学术]

刘爱运. 荧光增白剂在造纸过程中应用的研究[D].济南: 山东轻工业学院, 2011. [百度学术]

LIU A Y. Application of Fluorescent Whitening agent in Papermaking Process[D].Ji’nan: Shandong Insititute of Light Industry, 2011. [百度学术]

惠岚峰. 纸浆中荧光的研究进展[J]. 天津造纸, 2006(1): 20-24. [百度学术]

HUI L F. Research Progress of Fluorescence in Pulp[J]. Tianjin Paper Making, 2006(1): 20-24. [百度学术]

万金泉. 废纸脱墨纸浆中荧光增白剂的去除及其机理研究[J]. 华南理工大学学报(自然科学版), 2000(4): 71-74. [百度学术]

WAN J Q. Study on the Elimination Mechanism of Fluorescer in Deinked Pulp[J]. Journal of South China University of Technology (Natural Science Edition), 2000(4): 71-74. [百度学术]

惠岚峰, 徐立新, 刘 薇. 过醋酸蒸煮脱除棉浆荧光的工艺研究[J]. 天津科技大学学报, 2006(2): 33-35, 68. [百度学术]

HUI L F, XIU L X, LIU W. Study on Removal of Fluorescence in Cotton Linter Pulping with Peracetic Acid[J]. Journal of Tianjin University of Science & Technology, 2006 (2): 33-35, 68. [百度学术]

赵晓迪. 废纸回收利用对中国造纸产业碳减排的影响研究[D].北京: 北京林业大学, 2020. [百度学术]

ZAO X D. A Research on Impact of Waste Paper Recycling and Utilization to Chinese Papermaking Industry[D].Beijing: Beijing Forestry University, 2020. [百度学术]