摘要

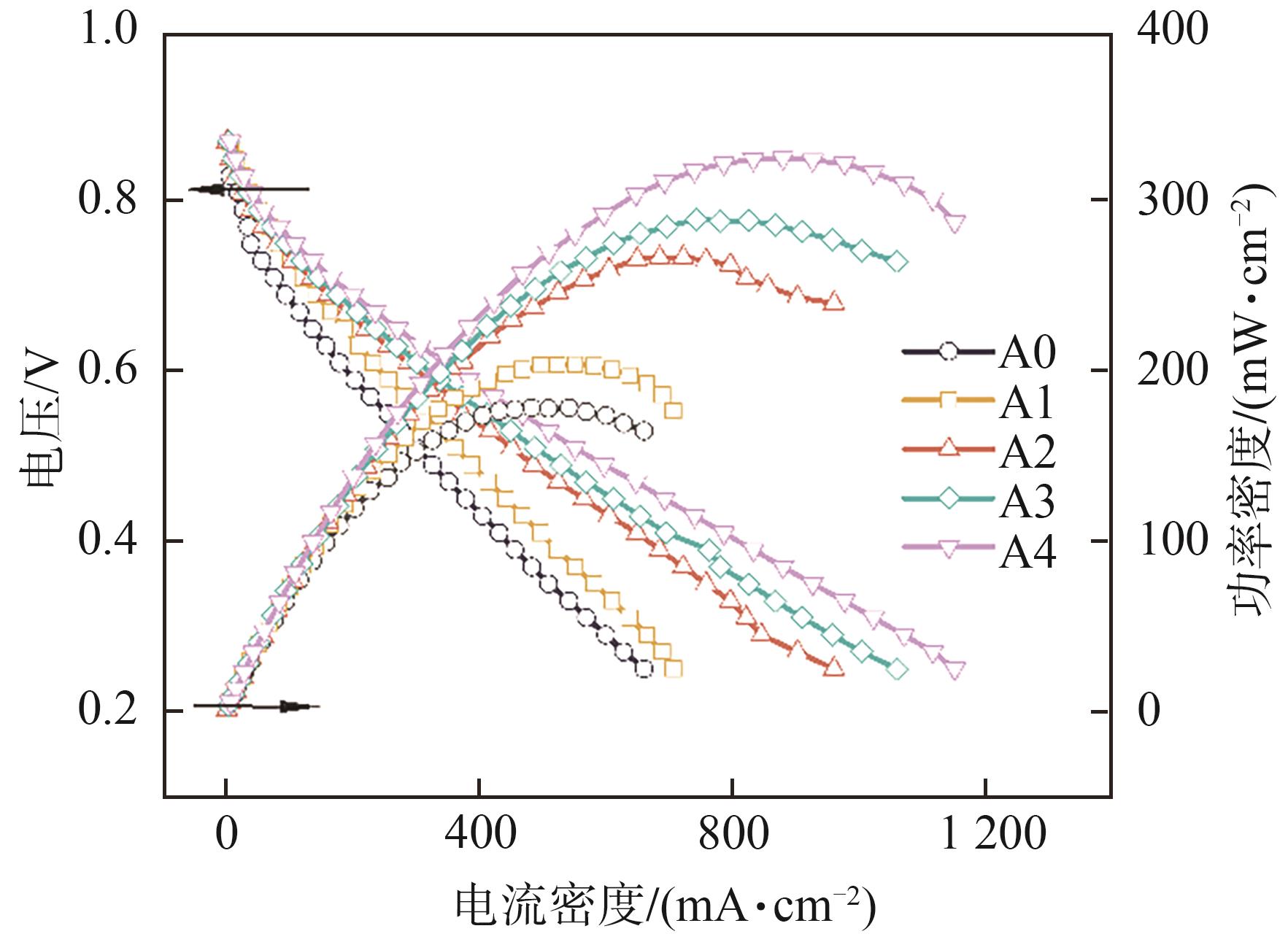

本研究探究了以纳米纤维素为酚醛树脂改性剂和成孔剂制备的质子交换膜燃料电池(PEMFCs)用碳纸性能,分析了纳米纤维素添加量对碳纸电阻率、透气性及机械强度等指标的影响,并测试了改性碳纸制备的电池性能。结果表明,与未改性碳纸相比,纳米纤维素添加量为0.20 g的改性碳纸电阻率降低了26.35%,其制备的PEMFCs功率密度峰值提高了81.56%,为325 mW/c

关键词

质子交换膜燃料电池(PEMFCs)因其能量转换效率高、无污染排放、稳定可靠等特点,在新能源汽车和便携式电源领域引起了广泛关

研究表明,CP具有多孔性,为氧、氢的运输和液态水的输出提供了充足的通

本研究以纳米纤维素为酚醛树脂的改性剂和成孔剂,通过对CP原纸进行改性酚醛树脂浸渍、热压和碳化,制备纳米纤维素改性CP,研究纳米纤维素添加量对CP的孔隙率、透气性、电导率和力学性能等综合性能的影响。此外,对组装好的PEMFCs进行极化曲线测试,分析纳米纤维素改性CP对燃料电池性能的影响。

首先称取12 g酚醛树脂溶解于无水乙醇中,超声搅拌5 min后,加入纳米纤维素,控制酚醛树脂浸渍液总质量为100 g,纳米纤维素质量分数分别为0、0.05%、0.10%、0.15%和0.20%,超声搅拌10 min,保证其在混合溶液中均匀分散,配制改性酚醛树脂浸渍液(具体命名参见1)。随后,将CP原纸浸渍于浸渍液中超声处理20 min,超声完成后用玻璃棒进行平铺,保证酚醛树脂渗透均匀,然后在80 ℃烘箱中干燥1 h去除溶剂,得到浸渍后CP。将浸渍后CP置于温度150 ℃、压力 4 MPa的硫化床热压1 h成形,以确保在碳化前充分固化和交联,得到热压后CP。最后,将热压后CP在高温管式炉中进行碳化,升温速率为10 ℃/min、烧结温度为1 100 ℃、保温时间为1 h,降温后得到纳米纤维素改性CP,分别命名为A0、A1、A2、A3、A4。

| 编号 | 酚醛树脂质量分数/% | 纳米纤维素质量分数/% |

|---|---|---|

| S0 | 12 | 0 |

| S1 | 12 | 0.05 |

| S2 | 12 | 0.10 |

| S3 | 12 | 0.15 |

| S4 | 12 | 0.20 |

采用多重光散射仪(Turbiscan,法国Formulaction公司)测定浸渍液的稳定性指数(TSI值)。使用扫描电子显微镜(SEM,SU-1510,日本Hitachi公司)观察CP表面形貌。使用压汞仪(AutoPore V 9620,美国Micromeritic公司)测定CP孔隙率。使用透气度测定仪(FX3000,瑞士TEXTEST公司)测定CP的透气度。使用四探针测试仪(RTS-8,广州四探针科技有限公司)测定CP的平面电阻率。采用通用机械试验机(KYD-2000NS,浙江天度科技有限公司)对CP的抗张力和弯曲强度进行测试。

将CP切割成2 cm×2 cm尺寸的薄块作为质子交换膜燃料电池(PEMFCs)的气体扩散层,然后与3 cm×3 cm的催化涂层膜组成3层膜电极组件(MEA)。催化涂层膜的厚度为45 μm。催化剂Pt/C阳极负载量为0.12 mg/c

测试前首先对PEMFCs进行氮气吹扫2 min,排除内部杂质气体,随后通入反应气体对单电池进行活化激活,活化面积为4 c

不同纳米纤维素添加量的改性酚醛树脂浸渍液的实物照片和多重光散射分析如

图1 不同纳米纤维素添加量的酚醛树脂浸渍液的动态分散示意图

Fig. 1 Dynamic dispersion diagram of phenolic resin solutions with different addition amounts of nanocellulose

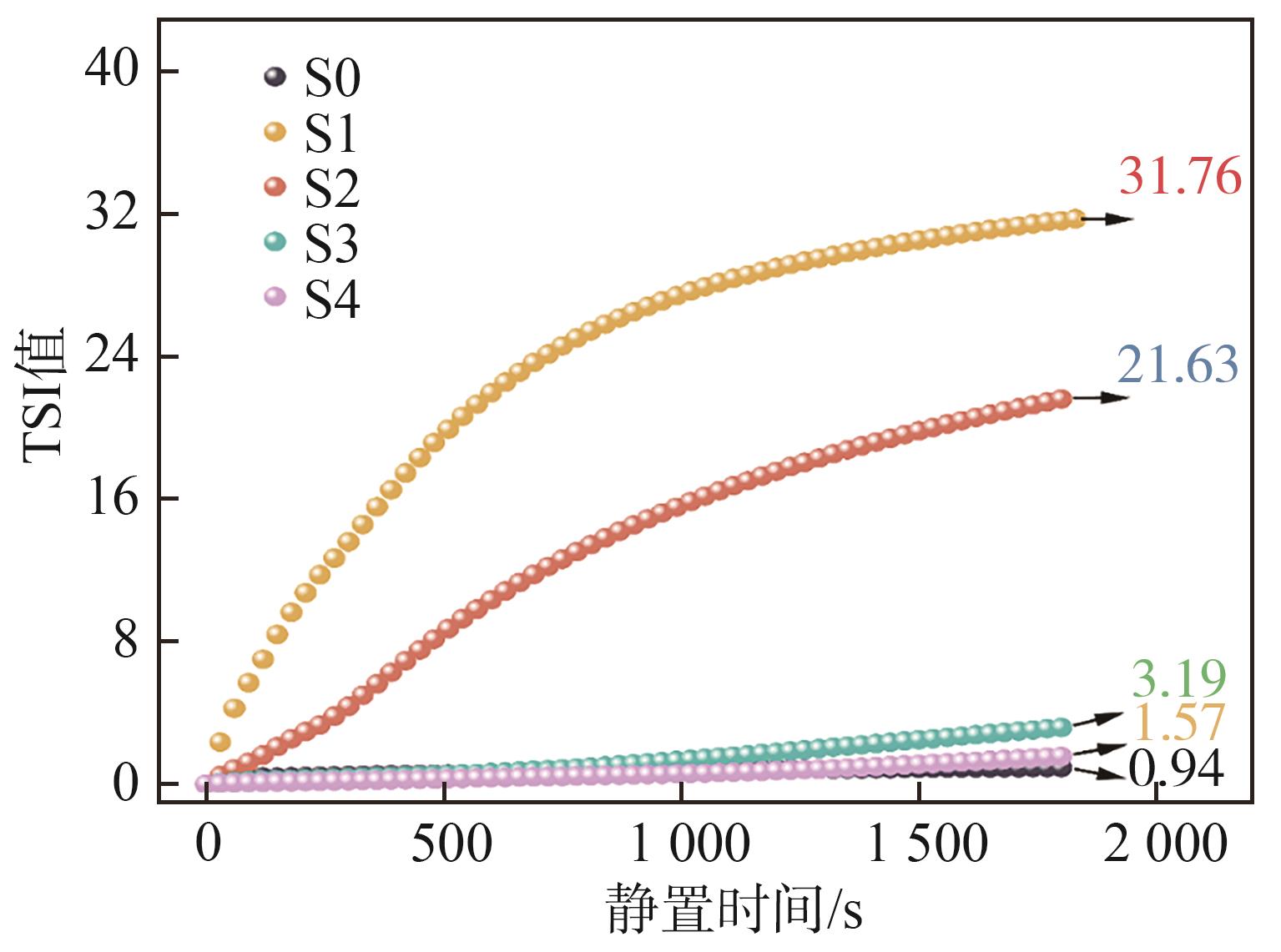

S0和不同纳米纤维素添加量的改性酚醛树脂浸渍液的TSI值如

图2 不同纳米纤维素添加量的酚醛树脂浸渍液的TSI值

Fig. 2 TSI value of phenolic resin solutions with different addition amounts of nanocellulose

对不同纳米纤维素添加量的纳米纤维素改性CP的微观形貌进行分析,结果如

图3 不同纳米纤维素添加量的纳米纤维素改性CP的SEM图

Fig. 3 SEM images of modified CP with different addition amounts of nanocellulose

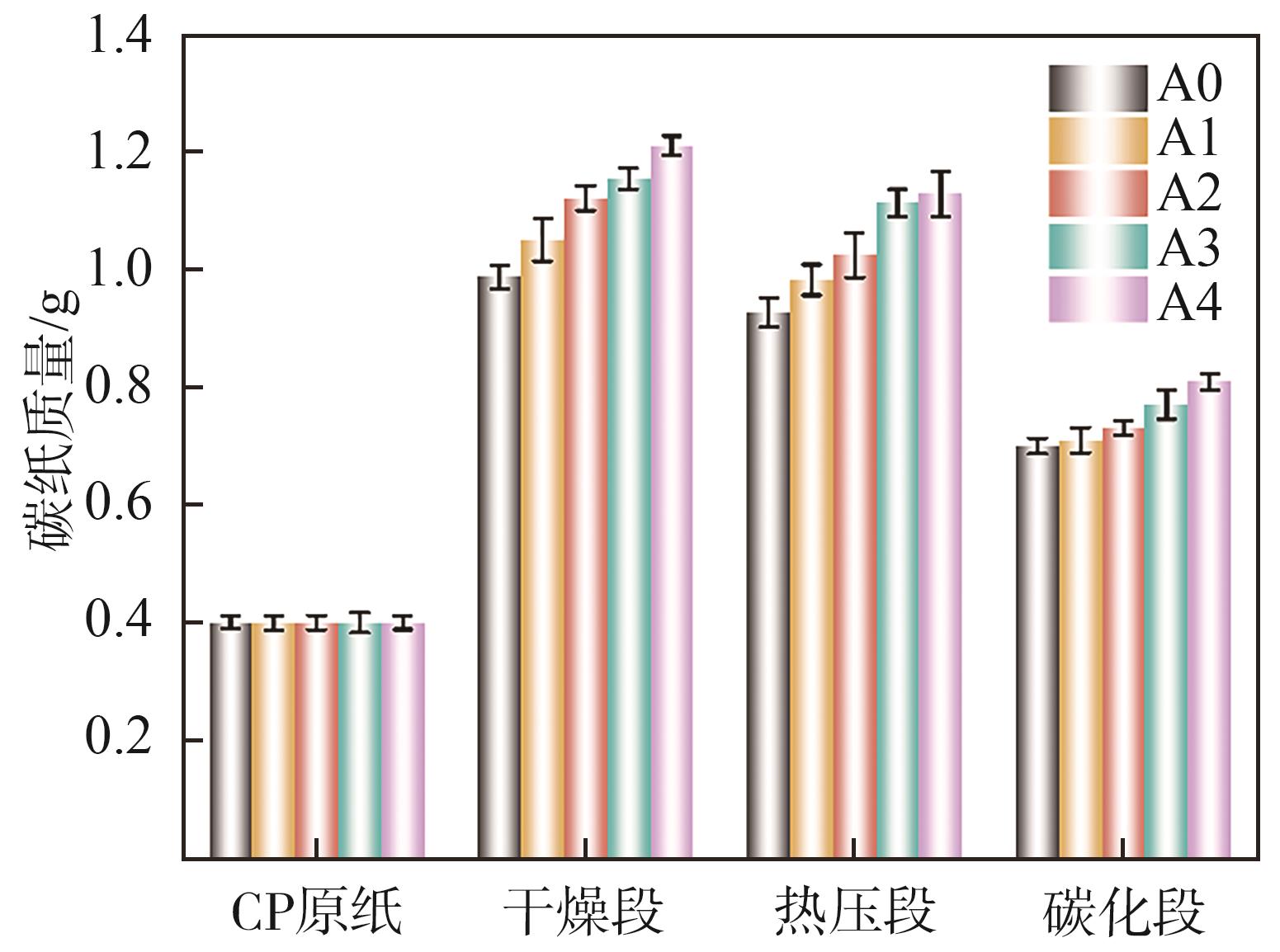

不同纳米纤维素添加量的改性CP在干燥段、热压段和碳化段的质量变化规律如

图4 不同纳米纤维素添加量的改性CP原纸在干燥、热压、碳化阶段的质量

Fig. 4 Quality of modified carbon paper base paper with different addition amounts of nanocellulose in drying, hot pressing, and carbonization stages

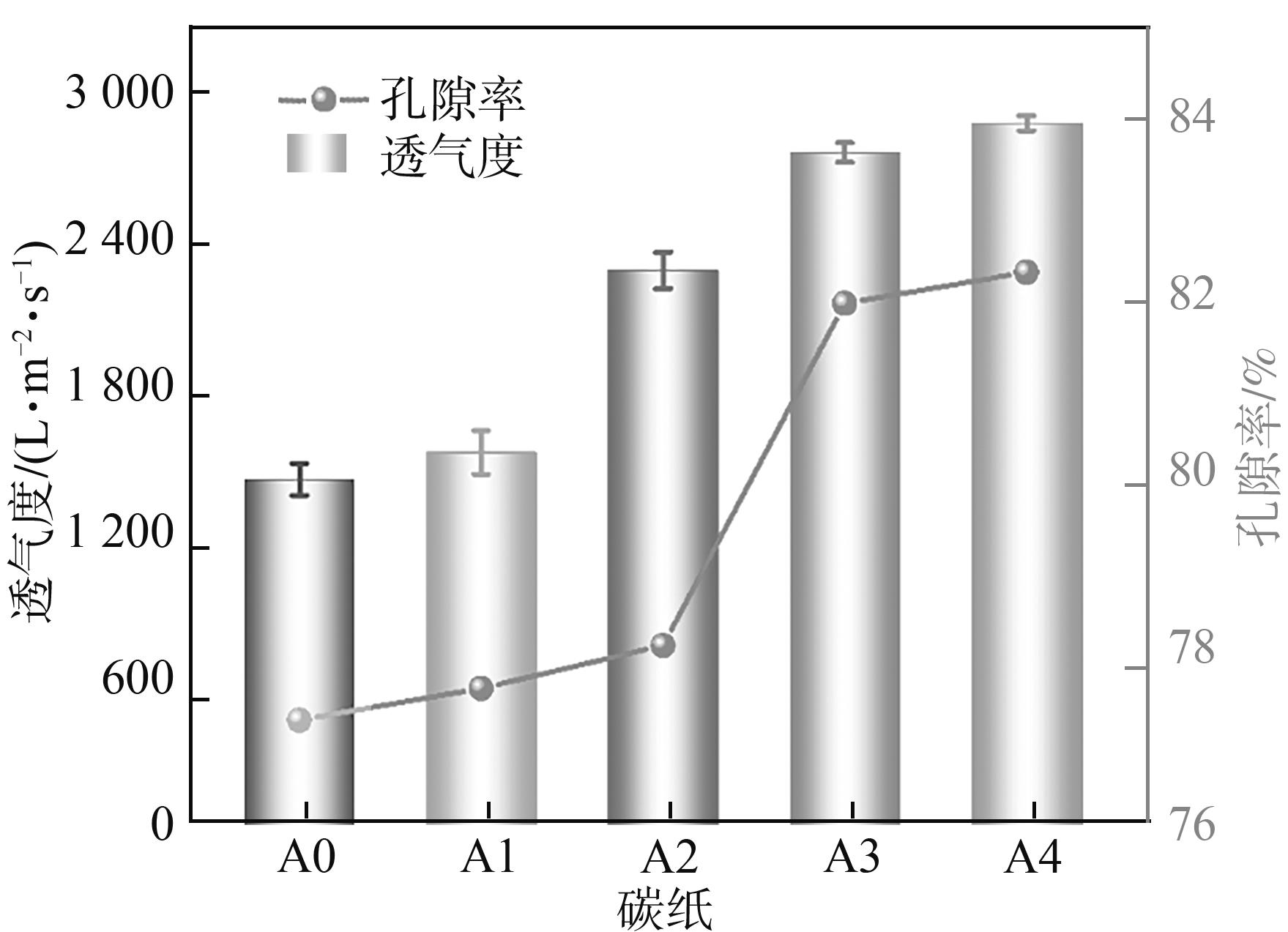

具有优异的孔隙连通性和透气度的CP被认为是PEMFCs电极的理想选择,可使整个电极区域具有电化学活

图5 不同纳米纤维素添加量的改性CP的透气度和孔隙率

Fig. 5 Permeability and porosity of modified CP with different addition amounts of nanocellulose

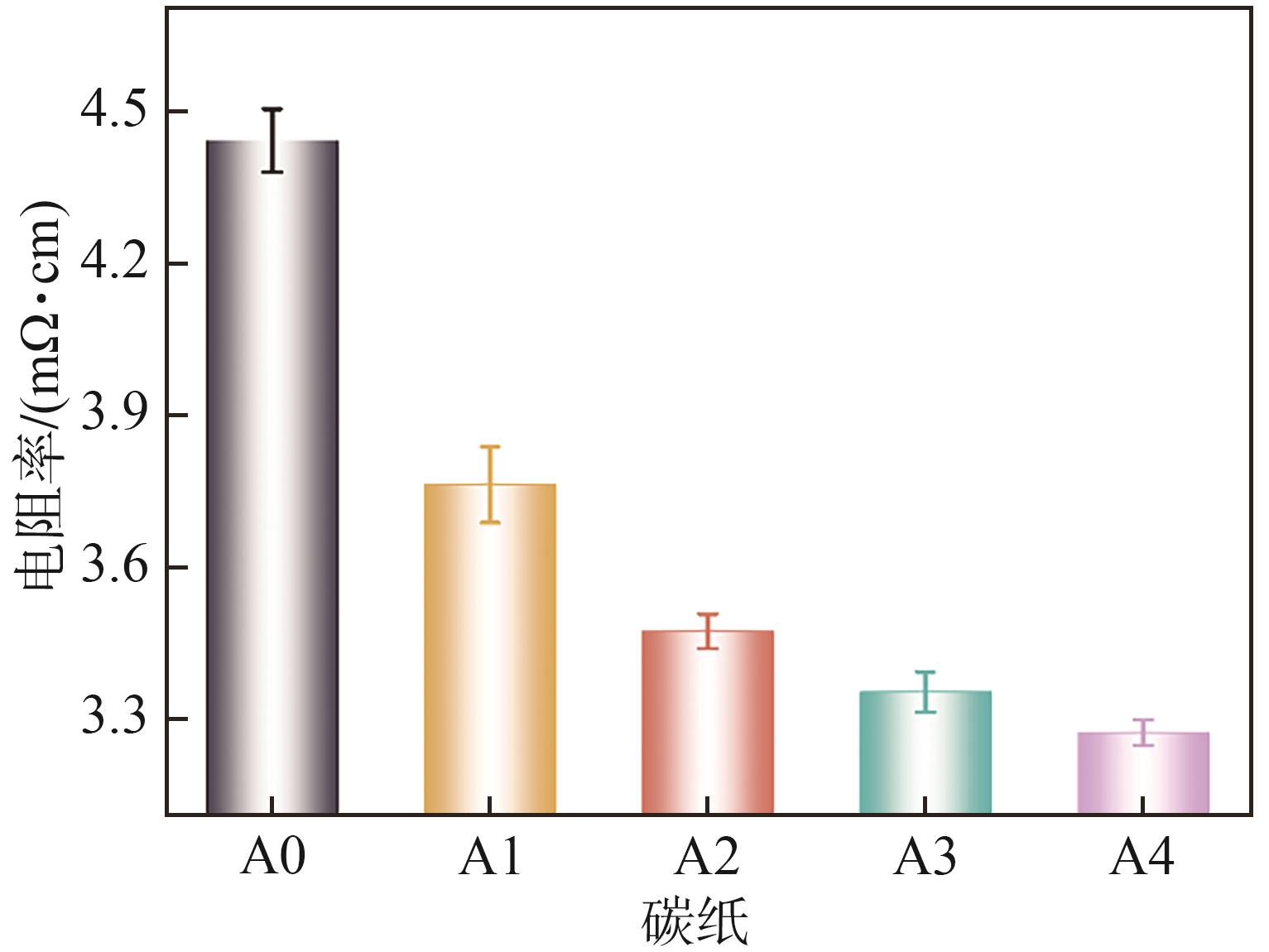

未改性CP和不同纳米纤维素添加量的改性CP的四探针电阻率结果如

图6 不同纳米纤维素添加量的改性CP的电阻率

Fig. 6 Resistivity of modified CP with different addition amounts of nanocellulose

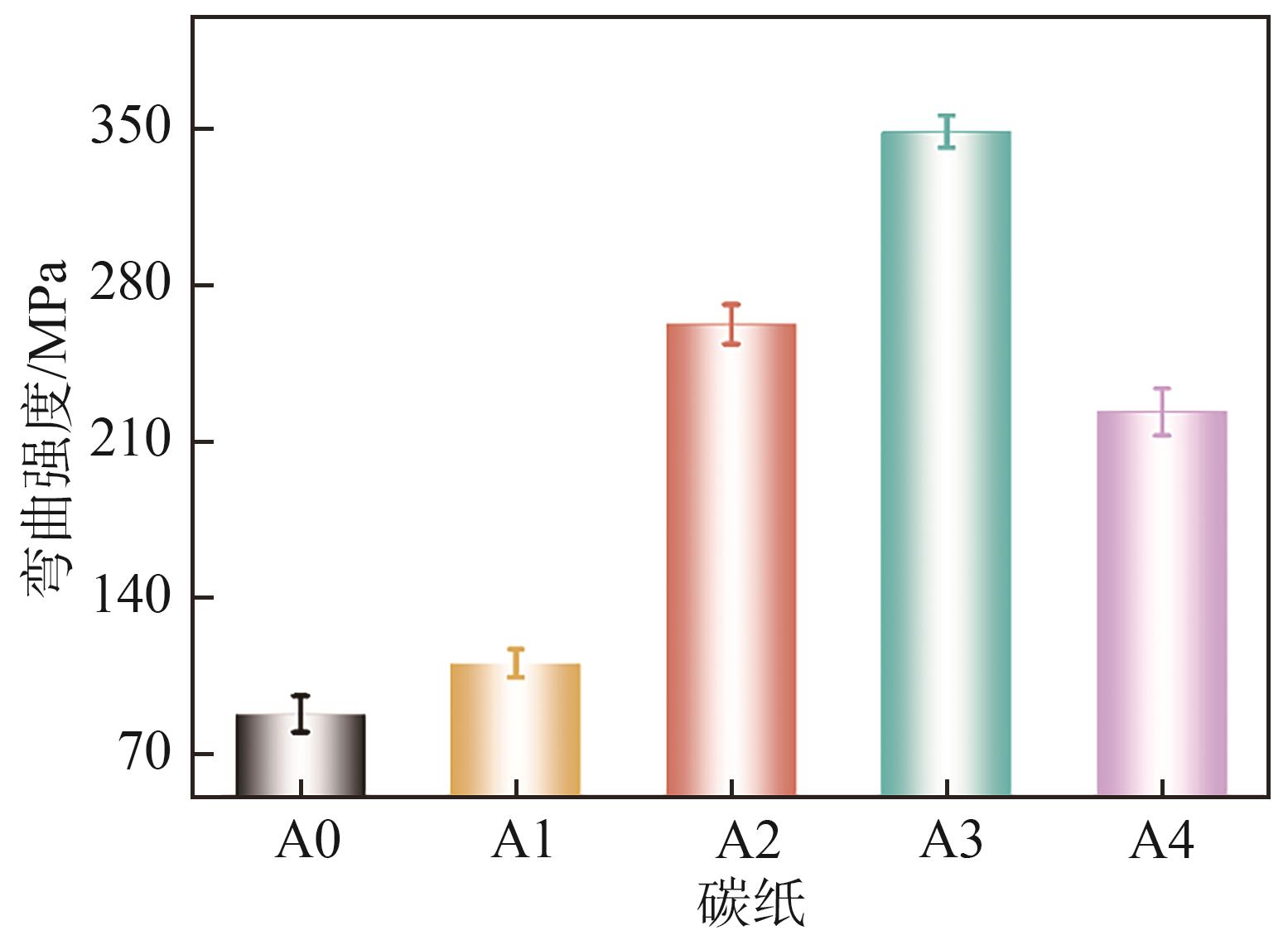

CP和不同纳米纤维素添加量的改性CP的弯曲强度分析见

图7 不同纳米纤维素添加量的改性CP的弯曲强度

Fig. 7 Flexural strength of modified CP with nanocellulose with different addition amounts of nanocellulose

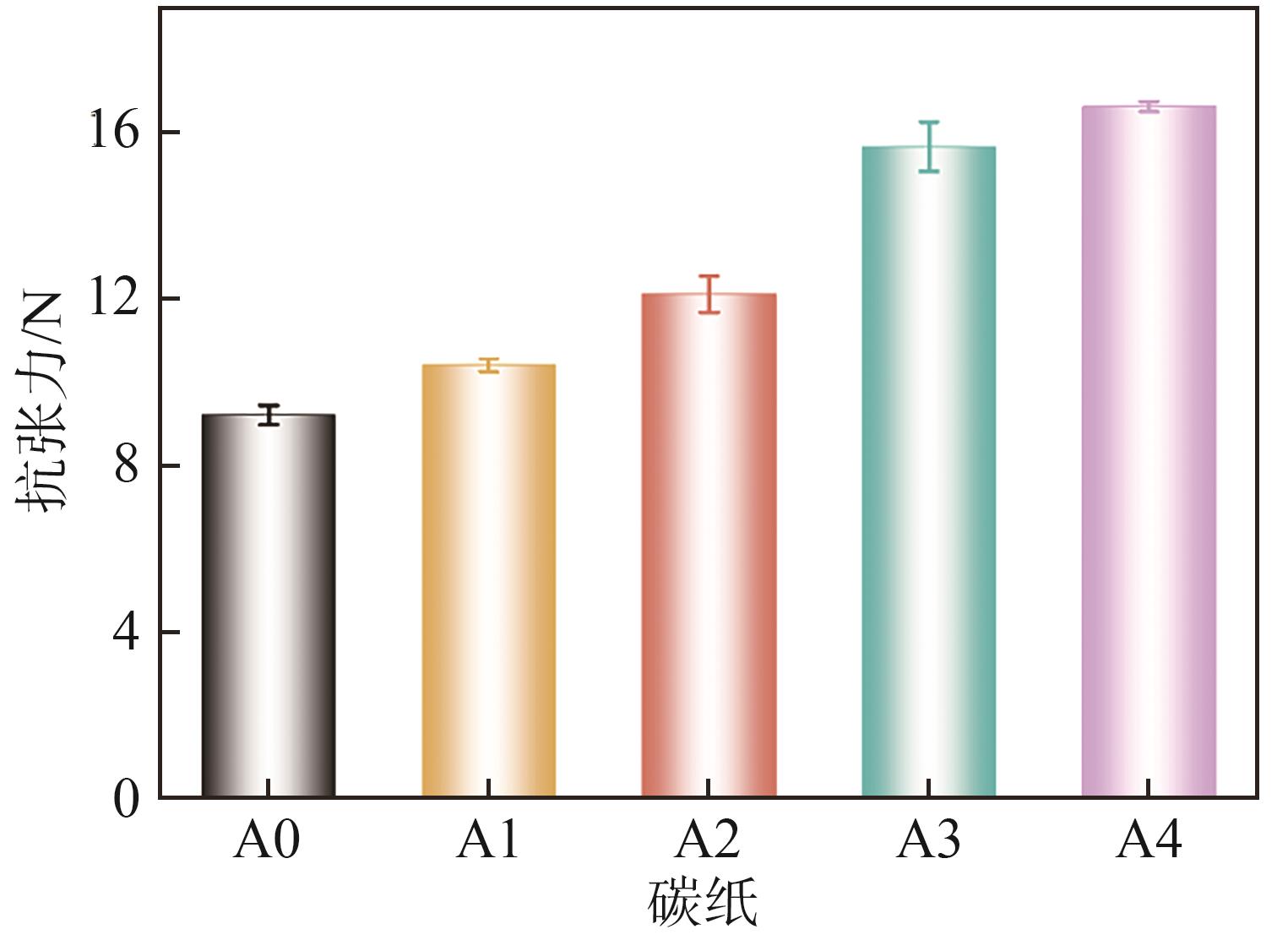

未改性CP和不同纳米纤维素添加量的改性CP的抗张力分析如

图8 不同纳米纤维素添加量的改性CP的抗张强度

Fig. 8 Tensile strength of modified CP with different addition amounts of nanocellulose

为了评价CP的应用性能,本研究使用未改性CP和不同纳米纤维素改性CP分别组装MEA,进行PEMFCs极化曲线测试(

图9 不同纳米纤维素添加量的改性CP的PEMFCs性能

Fig. 9 PEMFCs performance of modified CP with different addition amounts of nanocellulose

本研究通过纳米纤维素改性酚醛树脂浸渍液浸渍碳纸原纸,制备了高导电、高孔隙的纳米纤维素改性碳纸(CP)。

3.1 与未改性CP相比,纳米纤维素添加量为0.20%改性CP的平面电阻率降低至3.27 mΩ·cm、弯曲强度和抗张力分别增加至222.97 MPa和16.58 N、孔隙率和透气度分别升高至82.26%和2876 L/(

3.2 纳米纤维素添加量为0.20%改性CP组装的质子交换膜燃料电池峰值功率密度可达325 mW/c

参 考 文 献

袁晓君, 孙其忠, 刘江涛, 等. 添加气相生长碳纤维对改善碳纸性能的研究[J]. 中国造纸, 2023, 42(1): 33-37. [百度学术]

YUAN X J, SUN Q Z, LIU J T, et al. Study on Improving the Properties of Carbon Paper by Adding Gas-phase Grown Carbon Fiber[J]. China Pulp & Paper, 2023, 42(1): 33-37. [百度学术]

方滔. 硼催化石墨化对燃料电池用碳纸结构与性能的影响[D]. 广州: 华南理工大学, 2021. [百度学术]

FANG T. Effect of Boron Catalytic Graphitization on Structure and Properties of Carbon Paper Used in Fuel Cells [D]. Guangzhou: South China University of Technology, 2021. [百度学术]

陈辉, 沈志刚. 质子交换膜燃料电池用碳纤维纸的研究进展[J]. 合成纤维工业, 2021, 44(3): 78-83. [百度学术]

CHEN H, SHEN Z G. Research Progress of Carbon Fiber Paper for Proton Exchange Membrane Fuel Cells [J]. China Synthetic Fiber Industry, 2021, 44(3): 78-83. [百度学术]

胡蓉蓉, 李梦佳, 华飞果, 等. 两亲改性碳纤维制备质子交换膜燃料电池用碳纸的研究[J]. 中国造纸, 2020, 39(3): 15-21. [百度学术]

HU R R, LI M J, HUA F G, et al. Preparation of Carbon Paper for Proton Exchange Membrane Fuel Cells by Amphilic Modified Carbon Fibers[J]. China Pulp & Paper, 2020, 39(3): 15-21. [百度学术]

李梦佳, 马闻骏, 华飞果, 等. 氟化中间相沥青改性碳纸的研究[J]. 中国造纸, 2021, 40(5): 47-53. [百度学术]

LI M J, MA W J, HUA F G, et al. Study on Fluorinated Mesophase Asphalt Modified Carbon Paper[J]. China Pulp & Paper, 2021, 40(5): 47-53. [百度学术]

JALEH B, NASROLLAHZADEH M, ESLAMIPANAH M, et al. The Role of Carbon-based Materials for Fuel Cells Performance[J]. Carbon, 2022, 198: 301-352. [百度学术]

郭宇, 陈秀爽, 杨硕, 等. 燃料电池用 PAN/Lyocell 复合碳纤维纸的制备与性能研究[J]. 中国造纸, 2023, 42(5):147-155. [百度学术]

GUO Y, CHEN X S, YANG S, et al. Preparation and Properties of PAN/Lyocell Composite Carbon Fiber Paper for Fuel cell [J]. China Pulp & Paper, 2023, 42(5): 147-155. [百度学术]

MATHUR R B, MAHESHWARI P H, DHAMI T L, et al. Processing of Carbon Composite Paper as Electrode for Fuel Cell[J]. Journal of Power Sources, 2006, 161(2): 790-798. [百度学术]

XIE Z, TANG X, YANG P, et al. Carboxyl-terminated Butadiene-acrylonitrile-modified Carbon Paper for Use of Gas Diffusion Layer in PEM Fuel Cells[J]. International Journal of Hydrogen Energy, 2015, 40(41): 14345-14352. [百度学术]

MAHESHWARI P H, GUPTA C, MATHUR R B. Role of Fiber Length and Pore Former on the Porous Network of Carbon Paper Electrode and Its Performance in PEMFC[J]. Fuel Cells, 2014, 14(4): 566-573. [百度学术]

苑田忠. 木质纤维素微/纳米纤丝形态与流变特性关系及其在乳液中的应用[D]. 广州: 华南理工大学, 2023. [百度学术]

YUAN T Z. Relationship Between Morphology and Rheological Properties of Lignocellulosic Micro/Nano-fibers and Their Application in Emulsions [D]. Guangzhou: South China University of Technology, 2023. [百度学术]

LI M C, WU Q, SONG K, et al. Cellulose Nanoparticles: Structure-morphology-rheology Relationships[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(5): 821-832. [百度学术]

陈晓宇. TurbiScan 多重光散射仪在 AKD 乳液稳定性评估中的应用探讨[J]. 纸和造纸, 2021, 40(5): 24-29. [百度学术]

CHEN X Y. Application Development of Turbiscan on the Stability Evaluation of AKD Emulsio[J]. Paper and Paper Making, 2021, 40(5): 24-29. [百度学术]

DORIEH A, AYRILMIS N, POUR M F, et al. Phenol Formaldehyde Resin Modified by Cellulose and Lignin Nanomaterials: Review and Recent Progress[J]. International Journal of Biological Macromolecules, 2022, 222: 1888-1907. [百度学术]

MATHUR R B, MAHESHWARI P H, DHAMI T L, et al. Characteristics of the Carbon Paper Heat-treated to Different Temperatures and Its Influence on the Performance of PEM Fuel Cell[J]. Electrochimica Acta, 2007, 52(14): 4809-4817. [百度学术]

WASEEM S, MAHESHWARI P H, ABINAYA S, et al. Effect of Matrix Content on the Performance of Carbon Paper as an Electrode for PEMFC[J]. International Journal of Energy Research, 2019, 43(7): 2897-2909. [百度学术]

SEO J, PARK H, SHIN K, et al. Lignin-derived Macroporous Carbon Foams Prepared by Using Poly (Methyl Methacrylate) Particles as the Template[J]. Carbon, 2014, 76: 357-367. [百度学术]

MAHESHWARI P H, SINGH R, MATHUR R B. Effect of the Thickness of Carbon Electrode Support on the Performance of PEMFC[J]. Journal of Electroanalytical Chemistry, 2012, 673: 32-37. [百度学术]

HU M, CAO G. The Effect of the Backing Layer Design on the Mass Transfer in a Proton Exchange Membrane Fuel Cell[J]. Energy Conversion and Management, DOI:10.1016/j.enconman.2022.116086. [百度学术]

XIE Z, TANG X, YANG P, et al. Carboxyl-terminated Butadiene-acrylonitrile-modified Carbon Paper for Use of Gas Diffusion Layer in PEM Fuel Cells[J]. International Journal of Hydrogen Energy, 2015, 40(41): 14345-14352. [百度学术]

MAHESHWARI P H, GUPTA C, MATHUR R B. Role of Fiber Length and Pore Former on the Porous Network of Carbon Paper Electrode and Its Performance in PEMFC[J]. Fuel Cells, 2014, 14(4): 566-573. [百度学术]

DEBE M K. Electrocatalyst Approaches and Challenges for Automotive Fuel Cells[J]. Nature, 2012, 486(7401): 43-51. CPP [百度学术]